The eCommerce industry has seen exponential growth ever since the COVID-19 pandemic. Amazon recorded its highest $574.78 billion net revenue in 2023, which is almost double from $280.52 billion in 2019. Due to the boom in the eCommerce industry, many new eCommerce startups are launching every year.

Although eCommerce brands have many things to consider, optimized inventory management is one crucial activity. So, if you are also a startup and want to optimize inventory management, then this guide is for you. Here, we are uncovering all about inventory optimization and presenting a few proven optimization tips.

What is Inventory Management Optimization?

Inventory management optimization is the process of effective management of inventory levels to lower costs, ensure proper fulfillment of customer demands, and avoid situations of overstocking, stockouts, and backorders. It involves many activities, including setting optimal inventory levels, smartly forecasting demand, and managing storage.

Inventory optimization ensures efficient management of stock control by implementing tools, processes, technology, and best practices to have effective inventory tracking, optimized storage, and better demand forecasting.

Main Elements of Inventory Management Optimization

There are different elements to consider for inventory management optimization. Some of the key ones include:

- Inventory levels

- Demand forecast

- Lead time

- Inventory replenishment

- Inventory turnover

- Vendor management

In short, inventory optimization involves considering all the elements that have a direct or indirect impact on inventory management.

Importance of Inventory Optimization for eCommerce

Optimized inventory management for your eCommerce startup business can lead to many benefits as follows:

- Balance inventory levels

- Reduce costs

- Prevent overstocking, stockouts, and backorders

- Timely shipment

- Increase customer satisfaction

- Effective supplier relationships

- Minimize holding costs

- Lower risk of obsolescence

All the above benefits are crucial to driving your e-commerce startup for long-term success. So, let’s now shift our focus to how to optimize inventory management in e-commerce.

7 Tips to Optimize Inventory Management in eCommerce

There are multiple ways to optimize inventory management depending on business-to-business and product niche. Below we have shortlisted a few proven tips to optimize inventory that can work for most e-commerce businesses:

1. Choose the Right Inventory Management Technique

The first inventory optimization practice is to choose the right inventory management technique. There are many inventory management techniques to choose from. However, below are three common ones to consider:

- Just-in-Time Inventory Management: The just-in inventory management technique involves product stocking only when the customer requests it. This technique provides cost savings, reduces storage expenses, lowers the risk of dead stock, and leads to a smaller warehouse footprint. However, it can be risky and requires accurate demand forecasting.

- FIFO Inventory Optimization: The first-in, first-out (FIFO) technique involves dispatching items to customers in the order they are received. This technique leads to lower shelf life, reduces waste, and keeps warehouse circulation. It works best for perishable foods.

- ABC Analysis: The ABC analysis technique involves categorizing inventory into three categories. Category A involves low-quantity, high-value items. Category B involves moderate-quantity, moderate-value items. Category C involves high-quantity, low-value items. Once inventory is categorized this way, it leads to a customized restocking plan for every category.

2. Forecast Demand using Historical Data

Another important factor for effective inventory management optimization is to forecast demand. Although you never know when your sales suddenly increase or decrease, historical data can be useful for demand forecasting.

For that, carry out a thorough analysis of your past sales data. Look for sales cycles, demand patterns, lead times, peak season, and similar other insights. Based on that, you can make the right decisions about your inventory.

3. Regular Supply Chain Audit

Make sure to audit the supply chain regularly after a few months. In the audit, evaluate all the components of the supply chain, catch troubling trends (faulty products and returns), check lead time, perform competitor cost analysis, monitor holding cost, and much more. These audits will help you pinpoint issues and make the right decisions to optimize inventory management.

4. Enforce Safety Stock Inventory

Safety stock refers to the extra stock in the inventory to use in emergencies, like supply chain failure, sudden increase in demand, etc. So, calculate and arrange the safety stock inventory based on your sales and avoid inventory failure situations in unexpected situations.

5. Find the Optimal Reorder Time

Besides ensuring safety stock inventory, you should also determine the optimal reorder time. This is crucial to ensure that you don’t allocate excess capital to inventory.

To find the optimal reorder time, you need to determine the average lead time, analyze historical demand patterns, and evaluate the cost of holding inventory. Based on that, determine the inventory level when you want to reorder to avoid stockouts.

6. Optimize Warehouse Layout/Operations

To optimize inventory management, you have to also make sure that the products enter and leave the warehouse without interruption. For that, you have to look into your current warehouse operations and find ways to optimize the layout and all warehouse activities. It can be related to slotting optimization, efficient space utilization, implementing barcode scanning for proper tracking, etc.

7. Use Inventory Management Software

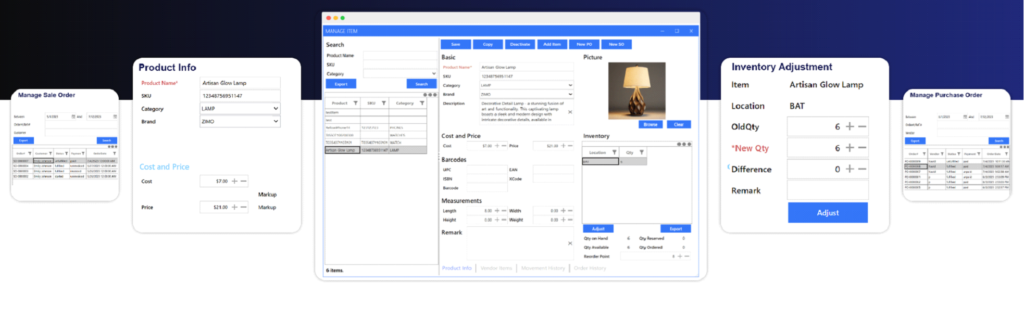

The last and most valuable tip for inventory management optimization is to use inventory management software. To better understand, let’s take C2W inventory management software as an example and see how it can streamline the whole inventory management.

C2W is a complete inventory management software that provides a centralized system to manage inventory in real-time. With C2W, you get:

- Holistic view of inventory levels in real-time.

- Centralized management of inventory across warehouses.

- Instant updates on stock levels and movements.

- Enhanced decision-making with insightful stock movement history.

- System-generated restocking for low inventory.

- Order fulfillment workflow for streamlined order processing.

- Automated reorder point alerts.

- Convenient barcode scanning.

In short, C2W is your all-in-one inventory management solution to handle all aspects of inventory management. On top of that, if you are using Shopify, C2W software can also integrate with Shopify and provide an efficient way to manage inventory.

Wrapping Up

Inventory management optimization is an essential process, especially for e-commerce startups who are looking for cost-effective and time-saving ways to run their business. Therefore, it’s time to optimize inventory management using the tips and tricks mentioned in this guide. However, you shouldn’t limit your optimization practices to the above 7 tips.

Keep evaluating your inventory needs and come up with strategic plans to optimize the management more effectively. For that, it is important that you use inventory management software like C2W to have a centralized view of inventory and easily spot improvement areas.