Master product shelf life management with practical strategies to reduce waste and improve inventory efficiency while meeting rising consumer expectations.

Product shelf life management is crucial for businesses working in the food and beverage industry. There is a growing demand among customers to get fresh and organic products. This urges firms to adopt strategies that minimize waste and maintain compliance with safety standards.

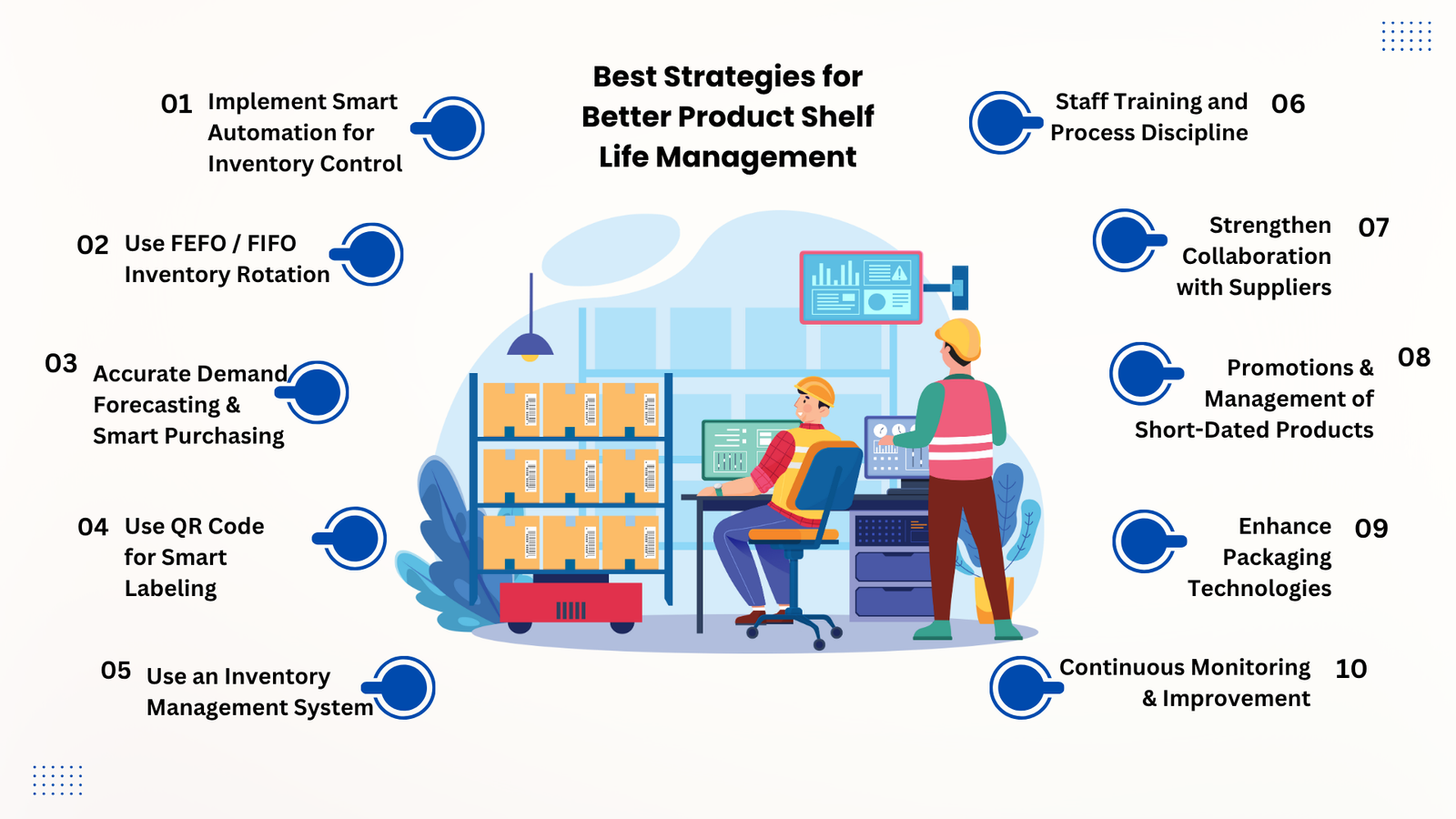

Did you know that about 30-40% of the US food supply goes to waste annually? While one business cannot solve this challenge alone, implementing smarter shelf life practices can reduce losses and improve product quality and customer trust. In this guide, we will look into the top 10 best strategies for product shelf life management for streamlined operations and reduced losses in today’s competitive market.

Implement Smart Automation for Inventory Control

Out of all the tips and tricks for effective product shelf life management, the most impactful one is implementing automation into your inventory control operations.

An automated system can streamline your operations and manage all the crucial aspects of your inventory without relying on a large human workforce:

- Climate-Adaptive Storage: An automated system can continuously regulate temperature and humidity as per the required conditions. With that, you can prevent spoilage and maintain freshness without constant human monitoring.

- Demand-Driven Replenishment: Instead of keeping fixed order quantities, smart pull systems supply inventory based on actual demand. This minimizes excess stock and optimizes ingredient use. In addition, it also cuts unnecessary storage costs.

- Proactive Re-Stock Notifications: Low-stock alerts ensure products are replenished at the right time. This balance keeps operations running smoothly and inventory levels stable without burdening your storage system and capital.

You won’t find a one-size-fits-all automated stock control system, but you can combine multiple tools to build an effective automated inventory control system.

Use FEFO / FIFO Inventory Rotation

The First-Expired-First-Out (FEFO) or First-In-First-Out (FIFO) method ensures items closest to expiration are used or sold first. Organize products so newer stock is placed behind older stock. Such rotation prevents items from lingering unnoticed and expiring, thereby maintaining freshness for consumers and reducing waste.

Accurate Demand Forecasting & Smart Purchasing

Product demands are not the same throughout the year. You must use historical sales data, seasonal trends, market behavior, and other factors to forecast demand precisely.

Order only what is needed as per your projected sales and avoid overstocking. This also means refining order sizes and delivery schedules with suppliers. Once your forecasts become accurate, it will help reduce surplus and lower storage costs with higher inventory turnover.

Use QR Code for Smart Labeling

Modern labeling demands detailed product information. Alongside barcodes, QR codes are now allowing businesses to embed far more information, including production dates, batch numbers, storage instructions, and traceability details.

When a QR code is scanned, your staff can gain instant access to product data. This helps monitor items at a precise level and simplifies inventory management.

Use an Inventory Management System

You don’t need advanced expertise in operations to manage product shelf life effectively. An all-in-one inventory management system can handle it for you.

C2W Inventory is a feature-packed inventory management tool that offers real-time inventory tracking across your single or multiple warehouse locations. It also provides automated reorder alerts to prevent shockouts or overstocking.

C2W Inventory supports FIFO practices and generates insightful reports. Moreover, it integrates purchasing, sales, and warehousing into one unified platform to help businesses streamline processes and keep products moving efficiently.

Check out this video to learn more about C2W Inventory: C2W Inventory Management System Demo | C2W Inventory

Staff Training and Process Discipline

Train employees on best practices, including how to apply FEFO/FIFO principles, handle products properly, follow storage methods, and recognize when a product is deteriorating. Regular audits and feedback loops can also ensure procedures are followed.

Engaged and well-informed staff can catch issues early before spoilage occurs. This culture of care supports every other strategy.

Strengthen Collaboration with Suppliers

The hassle of maximizing shelf life shouldn’t be limited to internal processes. It also requires close coordination with your suppliers.

Focus on building strong relationships with vendors so that you can negotiate flexible order quantities and align deliveries with actual demand. As your inventory system grows more sophisticated, suppliers can adjust shipments to keep products consistently fresh and help you reduce waste and cut storage costs.

Promotions and Management of Short-Dated Products

Identify products nearing their expiration early. Use discounts or bundle deals to sell them faster. You might also repurpose these items into prepared foods or donate if safe. As a result, you can reduce loss and signal to consumers that your brand cares about reducing waste and maintaining quality.

Enhance Packaging Technologies

There are now many innovative packaging options that can preserve product freshness. These include modified atmosphere packaging (MAP), vacuum sealing, edible coatings, and active packaging with oxygen scavengers or moisture absorbers.

These technologies help extend shelf life because they slow down spoilage and reduce oxidation. As a result, you can preserve product quality and safety for longer periods.

Continuous Monitoring & Improvement

The last strategy for effective inventory shelf life management is to establish ongoing monitoring and improvement practices. Measure key metrics, such as spoilage rate, inventory turnover, waste levels, storage conditions, etc.

Regularly review what’s working and what isn’t. Besides that, stay updated on new technologies, regulatory standards, and consumer expectations. You can also uncover issues early by considering feedback from staff and customers. Eventually, a system of continuous improvement will ensure that shelf life strategies stay effective as circumstances change.

Conclusion

Product shelf life management has become more important than ever due to rising customer expectations for freshness and stricter safety regulations. Businesses that are adopting proactive strategies (automation, smart labeling, inventory management software, and supplier collaboration) are gaining better control over their inventory.

Now is the time to upgrade your approach to inventory control. Follow the above practices and see how small moves will gradually lead to reduced waste, improved inventory management efficiency, and increased brand reputation and trust. Take action today and build a smarter approach to product shelf life management.