Imagine that your best-selling product just went out of stock. What could happen next is:

- 91% of shoppers would not wait for a restock and either switch to your competitor or abandon the purchase.

- 43% will buy from a different brand when out of stock.

- 9% switch retailers forever after one out-of-stock experience.

Stockouts account for 40% of lost sales. Facing stockouts is common, but it is preventable to a great extent. That’s what we will learn today in this guide. So, let’s first define stockout, highlight its causes, and then cover the best proven tips to avoid stockouts.

What is a Stockout?

A stockout is a situation that occurs when a business runs out of a particular product. It makes the product unavailable for customers to purchase. They have to wait till the inventory is restocked, which could take hours, days, or even weeks. Overall, stockouts lead to lost sales and damaged customer relationships and brand reputation.

The Causes of Stockouts

There are many reasons that can cause stockouts. It varies among businesses, but the common ones are as follows:

- Poor Demand Forecasting: Inaccurate predictions of customer demand lead to stockouts because businesses either underestimate how much stock is required or fail to anticipate sudden changes in demand.

- Supply Chain Disruptions: Any interruption in the supply chain, such as natural disasters, labor strikes, or shortages of materials, can delay the availability of products and cause stockouts.

- Supplier Delays: Delays from suppliers in delivering goods can cause inventory shortages, even if orders are placed on time.

- Inaccurate Inventory Records: Miscounts or technical issues with inventory systems can cause unexpected stockouts due to discrepancies between actual and recorded inventory levels. In fact, 26% of stockouts are due to inaccurate inventory data.

- Seasonality and Promotions: Unanticipated spikes in demand during seasonal peaks or promotional campaigns can quickly deplete stock.

- Product Quality Issues and Returns: High rates of defective products or returns can reduce available stock unexpectedly.

Other than the above, there are many more reasons that can lead to stockout scenarios, such as inventory theft, delivery problems, cash flow constraints, poor order management, and many more.

Impact of Stockouts on Your Business

Stockouts can have various negative impacts on your business. Some of the common impacts include:

1. Lost Sales Revenue

When products are out of stock, businesses miss immediate sales opportunities. This lost revenue adds up quickly and can be substantial over time because customers start switching to your competitors. In fact, 37% of Gen Z will search three other stores after an OOS.

2. Erosion of Customer Loyalty

Stockouts frustrate customers who often turn to competitors. This results in losing not just one sale but potentially future sales and long-term customer relationships.

3. Damage to Brand Reputation

Frequent stockouts damage a company’s image as a reliable and dependable brand. Customers may associate product unavailability with poor management. This leads to negative word-of-mouth and reduced brand trust. It also compromises market share and long-term profitability.

4. Increased Operational Costs

Businesses often bear extra expenses to address stockouts quickly, such as rush orders, expedited shipping, and overtime labor. These unplanned costs eat into profit margins and strain resources.

Read more: 10 Top Inventory Management Challenges and Their Solution

Best Practices to Prevent Stockouts

Did you know that reducing overstocks and stockouts lowers inventory costs by up to 12%? There are many ways to prevent stockouts, but keep in mind that there is no such thing as 100% prevention due to demand variability and supply chain uncertainties. For example, you may have reordered the inventory at the right time, but sudden supply delays due to weather conditions can still create stockouts.

The right strategy is to follow the best practices that can significantly minimize stockouts and improve inventory efficiency:

1. Improve Demand Forecasting

One of the key practices to prevent stockouts is accurate demand forecasting. Use historical sales data, seasonal trends, and other market insights to forecast your product(s) demand. You can take advantage of AI and machine learning tools for predictive analytics.

2. Maintain Safety Stock

Safety stock acts as a buffer against unexpected demand surges or supply disruptions. Determine safety stock levels based on demand variability and lead times. Also, regularly review and adjust safety stock to reflect changing market and supplier conditions.

3. Set Reorder Points

Establish reorder points that trigger replenishment orders before stock runs critically low. Automated inventory systems can send alerts when stock hits predefined thresholds. This helps to place an inventory order on time.

4. Conduct Regular Cycle Counting

Inventory cycle counting refers to an auditing technique where a small portion of inventory is counted on a regular and scheduled basis instead of counting the entire inventory at once. This practice verifies inventory records without disrupting daily operations.

5. Keep Inventory Level Healthy

Maintain a healthy inventory level to prevent a few out-of-trend orders from leading to stockouts. However, excessive inventory can also lead to overstocking. Therefore, you have to find a perfect range that does not lead to either stockout or overstocking.

6. Diversify Suppliers and Monitor Performance

Relying on multiple reliable suppliers reduces the risk of supply delays and inventory gaps. Establish relationships with backup suppliers and track metrics like on-time delivery and order accuracy to assess supplier reliability.

7. Use Inventory Software

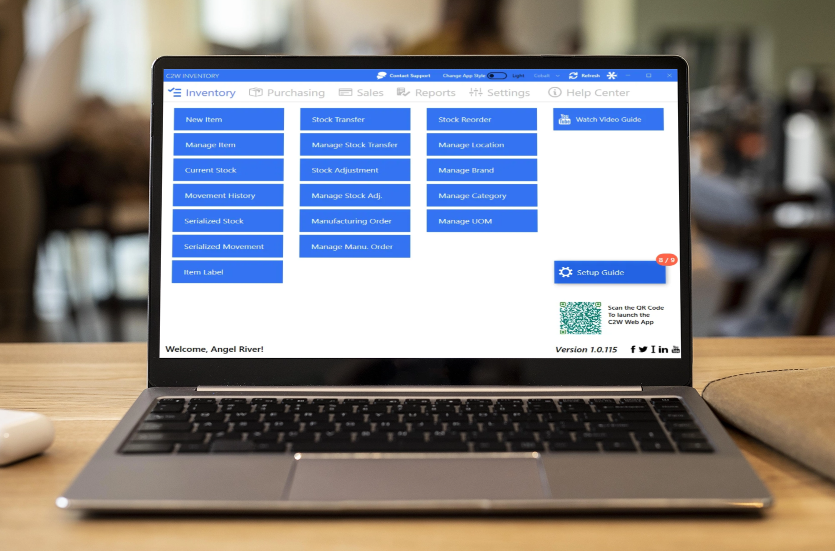

Many of the above practices are easily implementable if you have a reliable inventory management software running your inventory operations. For example, C2W Inventory is one feature-packed software solution that lets you have:

- Real-time inventory monitoring

- Automated reorder alerts

- Inventory management across multiple warehouses

- Supplier and purchase order management

- Reports on inventory turnover, stock aging, sales performance, etc.

- Integration with popular business tools and services

Overall, you get an all-in-one platform to manage your inventory and reduce stockout chances significantly.

Conclusion

Stockouts can have a devastating impact on business sales if the products remain missing from inventory for extended periods. They lead to immediate loss of revenue and long-term damage to brand reputation and customer loyalty. Therefore, it is recommended that businesses take every possible measure to prevent stockout scenarios, utilizing the best practices mentioned above and others that align with their specific business needs.

With regular monitoring and the right technology in place, you can maintain optimal inventory levels and ensure consistent product availability. Start implementing these strategies today to protect your sales and build a stronger business.