Efficient warehouse picking plays a critical role in successful order fulfillment. Choosing the right picking strategy not only improves speed and accuracy but also reduces operational costs. In fact, order picking represents 55% of warehouse operating costs and 70% of the operating time.

Two common methods used in warehouses today are picking by orders and picking by items (also known as batch picking). But how do you know which one is right for your operation?

In this blog, we will break down the differences between these two warehouse picking strategies, explain their pros and cons, and help you decide which one fits your workflow best.

What Is Picking by Orders?

Picking by orders, or single order picking, is a warehouse fulfillment method that involves picking one complete order at a time. A warehouse worker walks through the picking area with a list of all items needed for a single customer order and collects them in one pass.

For example, consider that in an online bookstore, a picker receives an order for three different titles. The worker walks through the shelves and collects each book one by one until the entire order is gathered. Then, the picker packs and ships it before starting the next order. This method is simple, reduces errors, and is ideal for small warehouses or operations.

Benefits of Picking by Orders

- Higher Accuracy: Focusing on one order at a time minimizes item mix-ups.

- Easier Training: A simple process makes onboarding new pickers faster.

- Better for Customized Orders: Ideal for orders that vary widely or require special handling.

- Flexibility in Workflow: Pickers can prioritize urgent or high-value orders without disrupting the entire picking process.

- Reduced Inventory Handling: Handling one order at a time minimizes unnecessary product movement and lowers the risk of damage or loss.

Drawbacks

- Inefficient for Large Volumes: Multiple trips to the same location increase labor and time.

- Not Ideal for Repetitive Items: Wastes time when multiple orders include the same SKUs.

- Slower Throughput: Processing one order at a time can delay overall fulfillment speed.

What Is Picking by Items?

Picking by items, or batch picking, allows workers to pick multiple orders at once by grouping items. For example, if 10 orders all contain the same product, the system generates a pick list to gather all units of that item in one trip. The items are sorted into individual orders afterward.

This method is effective in large warehouses with high order volumes containing common SKUs, as it minimizes repetitive trips to the same locations.

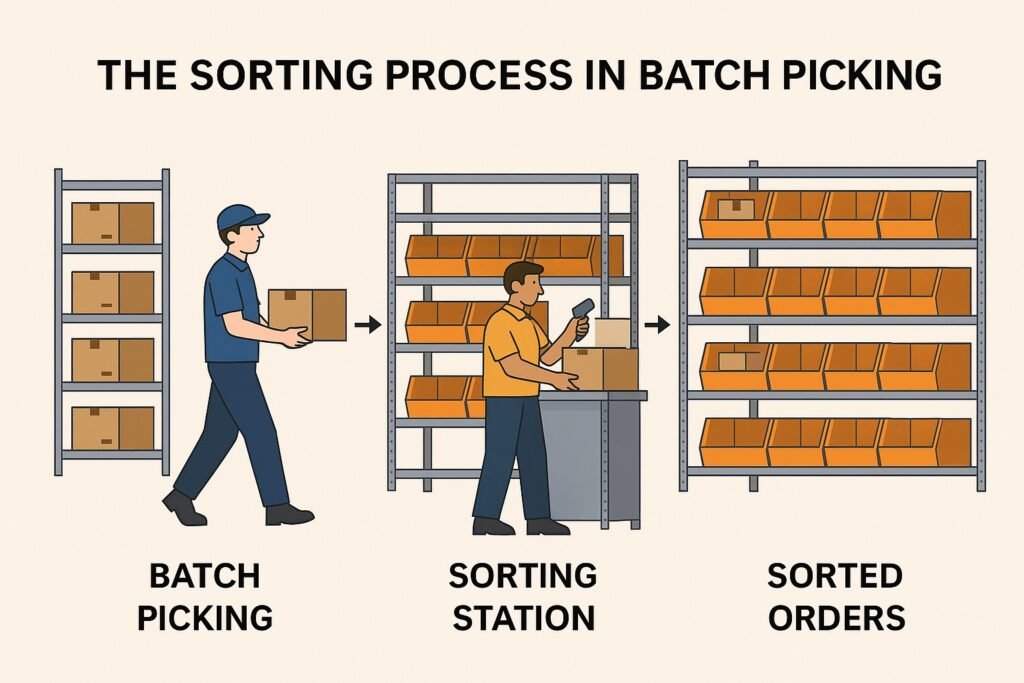

The Sorting Process in Batch Picking

For large eCommerce operations, sorting is a critical step in the batch picking workflow. The system typically splits orders into two categories:

- SLSP (Single Line Single Piece): These are single-item orders that can be picked and shipped directly—no sorting needed.

- MP (Multiple Line or Single Line Multiple Pieces): These orders contain multiple items or quantities and must be sorted after picking.

To streamline operations, many warehouses assign one team to focus on SLSP orders while another team handles MP orders.

Once items are batch-picked from the warehouse floor, they are brought to a sorting station and separated into the appropriate bins—each representing a different customer order.

At the sorting station, staff scan the picked items. The system checks whether the scanned item belongs to an existing order. If it does, the system directs staff to place it into the correct bin. If not, the system creates a new order bin and assigns the item to it. Once all the required items for an order are in place, the system alerts staff to remove and complete that order.

Clearly labeled sorting stations and real-time scanning instructions help ensure fast, accurate order fulfillment while reducing human error.

Benefits of Picking by Items

- Faster Picking: Reduces travel time and increases efficiency, especially for high-volume warehouses.

- Optimized Labor Use: Enhances worker productivity by enabling pickers to complete multiple orders simultaneously and minimize redundant movements.

- Scales Well: Perfect for warehouses processing hundreds or thousands of daily orders.

- Lower Operational Costs: Reduces labor expenses and equipment wear by cutting down on repeated trips and unnecessary handling.

- Improved Order Throughput: Speeds up the entire fulfillment cycle and enables faster order processing and shipping.

Drawbacks

- Requires Sorting: Items must be accurately sorted into the correct orders post-picking.

- More Complex Setup: Special warehouse management systems or software may be needed to avoid mix-ups.

- Higher Initial Setup Costs: Investing in technology and training to support batch picking can be costly.

- Increased Handling: Items are handled twice, once during picking and again during sorting, which can raise the risk of damage.

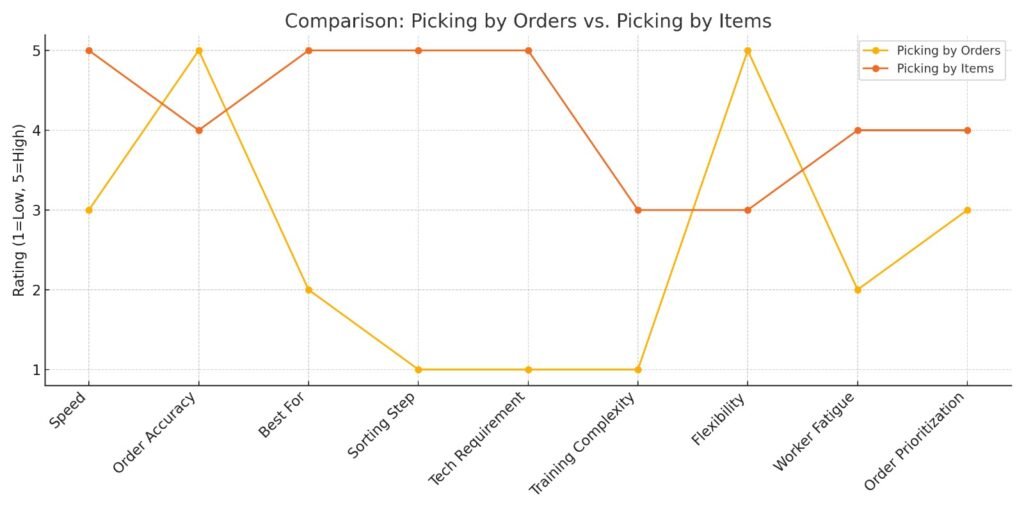

Features | Picking by Orders | Picking by Items |

Speed | Moderate | High |

Order Accuracy | Very High | Medium to high |

Best For | Small to midsize warehouses | High-volume, fast-moving operations |

Sorting Step | No | Yes |

Technology Requirement | Minimal | Recommended (WMS, barcode scanning) |

Training Complexity | Low | Moderate: need training on sorting and batch processes |

Flexibility | Adapts to unique or customized orders | Best suited for repetitive, similar orders |

Worker Fatigue | Higher due to repeated walking and handling | Lower due to optimized routes and batch processing |

Order Prioritization | Simple | Complex |

When to Use Each Picking Method

From the above picking by order vs. picking by items comparison, we can see that both have their pros and cons. So, the choice between them depends on business dynamics.

Use Picking by Orders if:

- Your business handles a smaller volume of orders.

- Orders are highly customized or vary widely.

- You need maximum accuracy without additional sorting steps.

Use Picking by Items if:

- You handle high volumes with lots of repeated SKUs.

- You want to reduce picking time and streamline labor.

- You have a system to sort items into the correct order after picking.

Can You Use Both Methods?

Absolutely! Many modern warehouses use a hybrid approach, choosing the picking method based on order type, item popularity, or customer priority. For example, you can batch pick standard orders and handle custom or urgent orders individually.

With the help of inventory software like C2W Inventory, you can switch between picking methods depending on your workload.

C2W Inventory is a powerful inventory management software that provides a smarter way to manage warehouse fulfillment tasks. Our software can generate pick lists based on order/items and assign picking tasks to workers to improve efficiency and reduce errors. Our system also supports barcode scanning, real-time inventory tracking, and performance analysis.

Final Thoughts

Choosing the right picking method for your warehouse isn’t about one being better than the other, it’s about what works best for your business needs. If you want to optimize your warehouse operations, start by reviewing your order volume, SKU repetition, and team size. Afterward, decide on whether you want to go with picking by order vs. picking by items or use the hybrid model.

📺 Want to see these strategies in action? Watch our quick YouTube video here to simplify your decision-making.

Ready to improve your warehouse picking process? Try C2W Inventory for streamlined order and batch picking—no complicated setup needed.