Optimize your warehouse with the right bin structure. Understand each bin’s role and improve order fulfillment from receiving to shipping.

Efficient warehouse management starts with a solid bin structure. Each bin in your warehouse plays a key role in product flow, from the moment goods arrive to the time they ship out.

Regardless of whether you operate a small distribution center or a large fulfillment facility, understanding the various bin types is crucial for maintaining smooth operations, minimizing errors, and facilitating faster picking.

Let’s walk through the main bin location types, their roles, and how they can be optimized in your warehouse.

1. Receiving Bin

The receiving bin is the first stop for incoming inventory. It’s typically located at or near the dock doors, where vendors deliver pallets or packages. This bin serves as a temporary holding area where goods are unloaded and scanned before being moved to their designated storage locations.

For example, FreshMart is a mid-sized grocery distribution center supplying fresh produce, packaged goods, and household items to retail stores across the region. When FreshMart’s trucks arrive at the dock, pallets of fresh produce and packaged goods are unloaded directly into the receiving bins located right next to the dock doors. These bins are clearly marked and separated by product category, such as dairy, produce, dry goods, etc.

Purpose: Temporarily hold newly delivered goods before they are inspected and put away.

Best Practices:

- Use a dedicated space near the dock or temporarily use aisle space if constrained.

- Ensure that receiving bins do not block high-traffic areas, such as pick paths or put-away zones.

- Clearly mark receiving areas to avoid mix-ups.

2. Put-Away Bin

The put-away bin is where products go after they are received and scanned. It involves organizing and storing items in their optimal locations, such as racks, shelves, or pallets. This later helps in easily accessing them for picking or replenishment. Moreover, it is typically placed above the picking locations in a racking system.

For example, at FreshMart, bulk cases of canned vegetables are stored in put-away bins located on higher racks at the back of the warehouse, away from fast-moving picking bins. This placement keeps the high-quantity stock organized and out of the way until needed for replenishment or large orders.

Purpose: Store full pallets or cases until they are needed for replenishment. Additionally, it maximizes space utilization, reduces travel time for warehouse staff, and enhances inventory accuracy.

Best Practices:

- Use vertical space efficiently by stacking put-away bins above picking bins.

- Ensure clear labeling and system tracking for smooth replenishment.

- Don’t use put-away bins for picking unless using a combined method (see below).

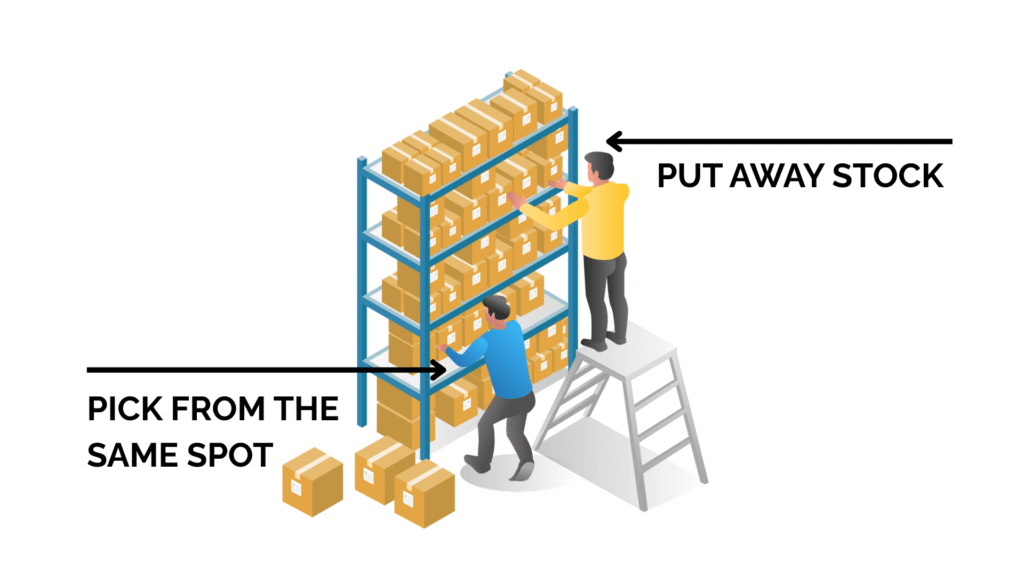

3. Put-Pick Bin

The put-pick bin serves a dual purpose. It allows products to be put away and picked directly from the same location. This type of bin is typically used for fast-moving items, as it enables quick replenishment and efficient order picking without the need to transfer stock between separate storage areas.

For example, at FreshMart, fast-selling items like milk cartons and bread are stored in put-pick bins located at waist height near the packing area. This setup allows staff to put newly received stock directly into these bins and pick from them immediately to fulfill orders. Overall, this minimizes handling time and speeds up the order fulfillment process.

Purpose: Streamline handling for high-velocity SKUs.

Best Practices:

- Use for items with high turnover that don’t require pallet breakdowns.

- Ensure accessibility for both inbound and outbound tasks.

- Keep put-pick bins near packing or high-volume picking zones.

4. Picking Bin

The picking bin is where warehouse staff go to pick products for order fulfillment. These warehouse picking bins are strategically placed at eye level or within easy arm’s reach to maximize picking speed and reduce worker fatigue.

For example, at FreshMart, popular grocery items like snacks, dairy products, and beverages are stored in picking bins located on racks near the packing stations. These bins hold smaller quantities of inventory specifically allocated for daily order fulfillment. Pickers use handheld scanners to locate and retrieve items from these bins. This minimizes travel time, reduces errors, and helps fulfill tight delivery schedules.

Purpose: Store broken-down cases or individual items ready for order picking.

Best Practices:

- Place picking bins in the lower sections of racks.

- Avoid using upper racks for picking unless space is extremely limited (and always prioritize safety).

- Regularly replenish picking bins from put-away locations.

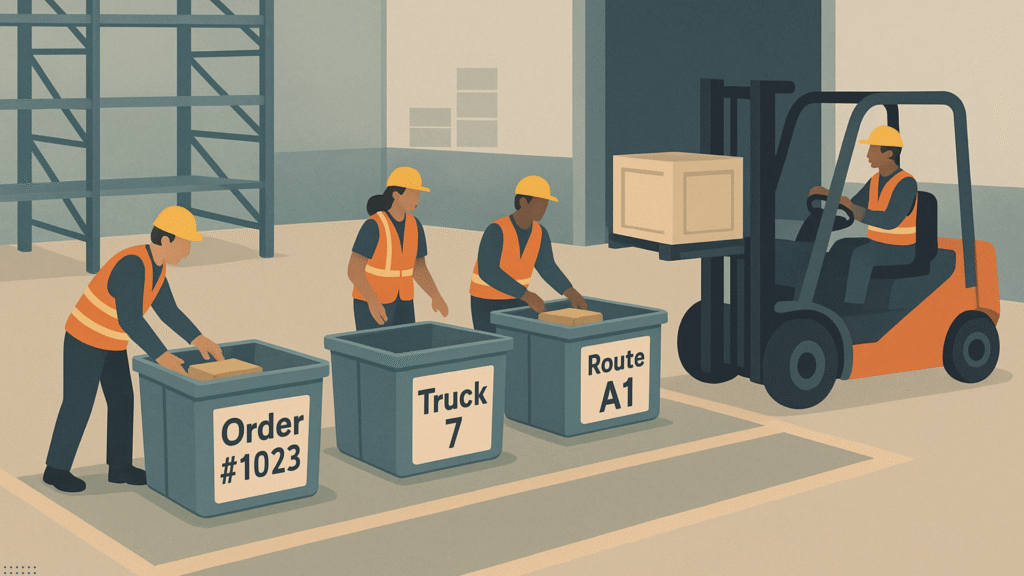

5. Staging Bin / Shipping Bin

Once an order is picked and packed, it needs to be temporarily staged before shipment. Staging bins hold these packed or pre-packed orders until they are ready to go out. Proper use of staging bins helps prevent shipment errors and reduces last-minute delays.

For example, at FreshMart, packed grocery orders are placed in staging bins near the loading docks, sorted by delivery route. This setup allows the shipping team to quickly load trucks in the correct sequence. This results in timely dispatch and reduced handling.

Purpose: Act as a buffer area for outgoing shipments.

Best Practices:

- Use floor-marked zones or shelving units based on delivery trucks or carriers.

- Label each staging bin with order, truck, or route info.

- Use scanning to track which order is in which staging location.

Read more: Picking by Orders vs. Picking by Items: Which Strategy Fits Your Warehouse?

6. Damaged / Returns Bin

Inevitably, some products will be returned by customers or identified as damaged during receiving or picking. These items should be immediately scanned and placed into a dedicated damaged or returned bin to prevent them from re-entering regular inventory. This bin acts as a quarantine area where items await inspection, disposition, or processing, such as repair, restocking, or disposal.

For example, at FreshMart, returned grocery items or damaged goods discovered during quality checks are promptly placed in a marked returns bin located near the receiving area. This process helps maintain inventory integrity and prevents shipping errors involving defective products.

Purpose: Segregate unusable or returned inventory from active stock.

Best Practices:

- Place the clearly labeled damaged bin in a quiet corner of the warehouse.

- Use red tape or signage to visually separate this zone.

- Implement a regular cycle count and write-off process for damaged inventory.

Final Thoughts

Understanding and organizing your warehouse using different bin types improves inventory accuracy, speeds up operations, and enhances safety. Each bin has a purpose, and using them correctly helps your team work smarter, not harder.

Whenever you are building your bin system from scratch or refining an existing layout, always align bin types with your warehouse flow and product behavior.

Here’s a quick video breaking down the different types of bins and how using them right can save you time, reduce errors, and speed up fulfillment.

Looking to digitize and streamline your bin tracking? C2W Inventory lets you set up, scan, and manage bin locations with ease, from receiving to shipping. It provides real-time visibility into inventory levels and movement, which helps maintain accurate stock counts and improve operational efficiency.

Let us know if you want a demo or help optimizing your bin structure!