Warehouse picking is a process to pull out products from warehouse to fulfill orders. Stick around to learn all about it in this comprehensive guide.

Warehouse picking is the heartbeat of any order fulfillment operation. Your ability to pick and ship orders quickly and accurately has a direct impact on operational efficiency and customer satisfaction, no matter if you are running a small e-commerce business or managing a growing warehouse.

Choosing the right warehouse picking method is essential to streamlining operations, improving order accuracy, and reducing costs. However, many businesses aren’t aware of these methods and the related best practices.

In this guide, we will break down what warehouse picking is, why it matters, the most common picking methods, and how to choose the right one for your business.

What Is Warehouse Picking?

Warehouse picking is the process of retrieving products from storage locations (such as shelves or bins) to fulfill customer orders. It involves selecting the right quantities and product types mentioned in each order.

Typical steps involved in a warehouse picking process include:

ORDER RECEPTION

ITEM LOCATION

Locate required items within the warehouse using a picking system.

PRODUCT RETRIEVAL

Travel to storage locations and pick the correct quantity of each product.

VERIFICATION

Verify picked items against the order to ensure accuracy.

TRANSFER

Transport picked items to the packing or staging area and update inventory.

Overall, warehouse picking is one of the most labor-intensive and time-consuming tasks in warehouse operations. Every order triggers a picking task, which requires someone (or something) to go get the items, package them, and get them ready for shipping.

Why Warehouse Picking Matters

Accurate and efficient warehouse picking is not a choice but a necessity for any scale of business. A poor picking process can cause delays, order errors, and unhappy customers. All these attributes lead to lost revenue and damaged reputation.

A proper warehouse picking system is essential to:

Deliver Orders On Time

Efficient warehouse picking is crucial to meeting customer expectations. In fact, 23% of shoppers will not buy from the store again after a delayed delivery.

When orders are picked and delivered timely, it leads to customer satisfaction, drives loyalty, and increases repeat purchases.

Reduce Returns Due to Wrong Items

Did you know 23% of returns are just because of shipping the wrong items? Accurate warehouse picking reduces the chances of shipping the wrong items. It ensures that the correct items are picked and shipped, which saves on reverse logistics costs and maintains customer satisfaction.

Keep Labor Costs Low

Warehouse picking involves planning optimized routes and placing high-demand items within easy reach. This leads to reduced labor costs associated with order fulfillment and boosts profitability.

Maximize Warehouse Productivity

Effective warehouse picking enhances overall productivity. It minimizes wasted time and motion, as pickers can quickly and accurately locate and retrieve items. Overall, the entire warehouse operation becomes more efficient.

Common Warehouse Picking Methods

Choosing the right picking method depends on your order volume, product variety, and warehouse layout. Moreover, it is essential to understand the fundamental difference between picking by orders versus picking by items to optimize your workflow (we will explore this distinction in detail in our upcoming blog).

Here are the most widely used picking methods:

Single Order Picking

Single order picking method involves picking and packing one order at a time. It is best for small businesses or low order volumes, where a business fulfills a large number of individualized customer orders of varying items. Since the picker focuses on one order at a time, it leads to higher accuracy.

Pros

- Easy to implement

- Higher order accuracy

- Good fit for high SKU variety per order

Cons

- Slower order processing, especially in large warehouses

- Labor-intensive

- Not suited for high-volume environments

Batch Picking

Batch picking method involves pickers collecting items for multiple orders in one trip. They group similar SKUs to pick them in one round. This method is useful to fulfill several orders simultaneously, but requires a sorting step during the packing stage. It is ideal for businesses who process a large number of small orders.

Pros

- Reduced labor costs

- Fast processing of similar orders

- Increased efficiency

Cons

- Not suited for unique or large orders

- Complex sorting step

- Chances of mistakes

- No flexibility for urgent orders

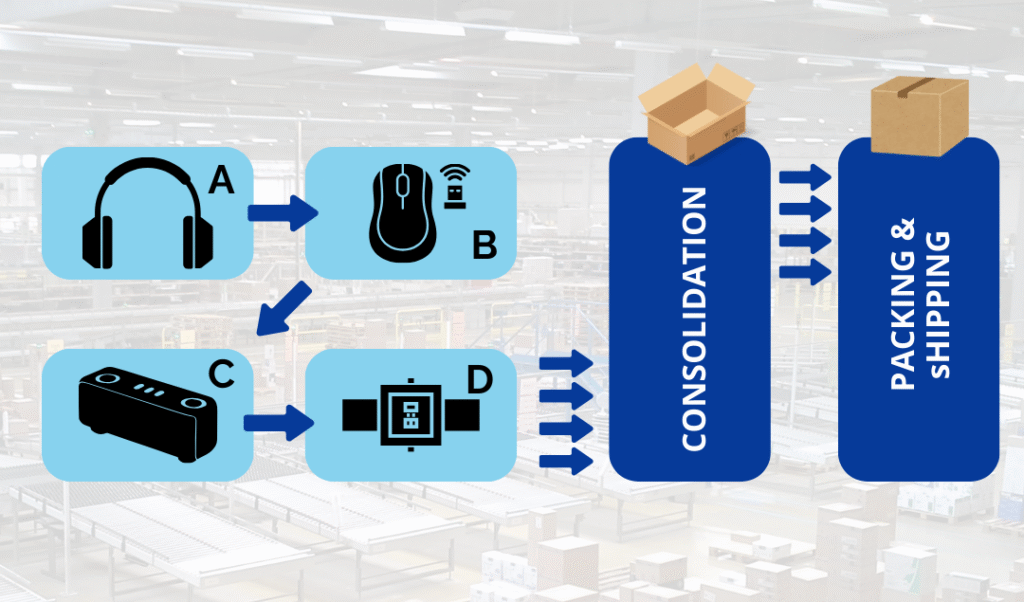

Zone Picking

As the name implies, zone picking method divides the warehouse into zones. Each worker picks items from their assigned zone. Afterward, the picked items are passed physically or through conveyor to be consolidated with items from other zones and complete the order. This warehousing picking method is best in large warehouses to save travel time and increase order picking speed.

Pros

- Less aisle congestion

- Faster order picking speed

- Less travel time

- Increased picker efficiency

Cons

- Require complex coordination

- Chances of inefficiencies

- Higher initial setup cost

- Unequal workloads if some zones are busier than others

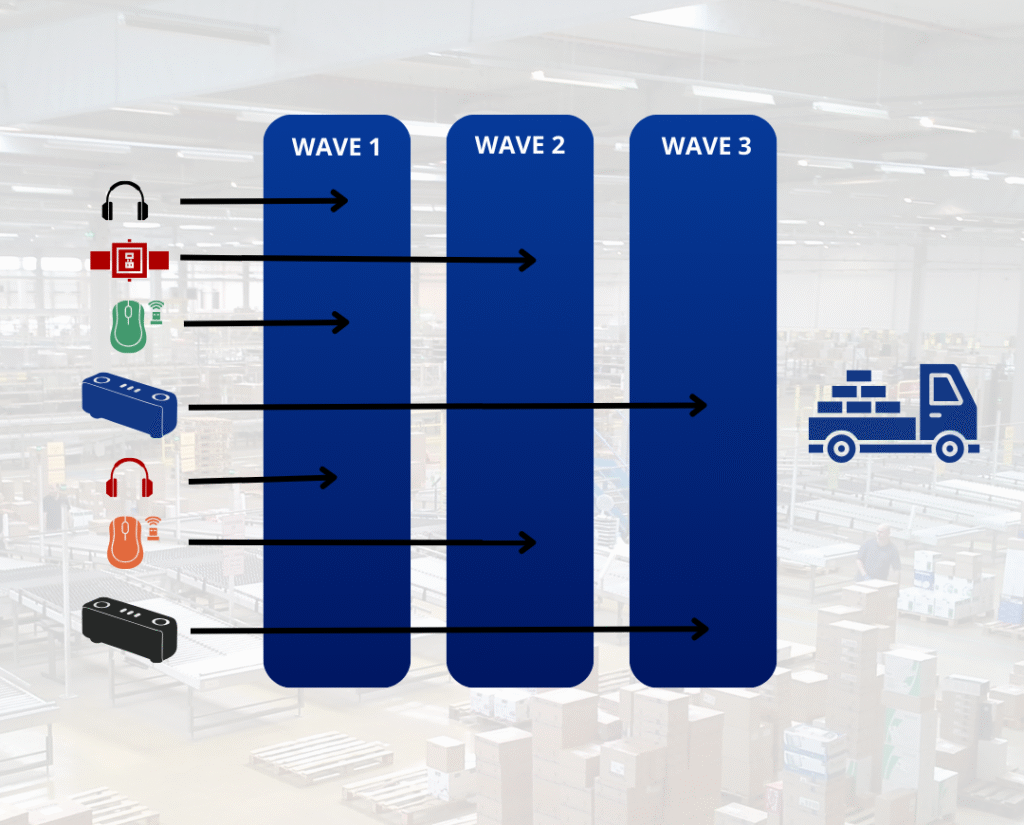

Wave Picking

Wave picking is a unique type of order picking in which orders are grouped by delivery time, carrier, or other factors. Picks are scheduled in waves to align with shipping schedules. It can be used along with zone or/and batch picking. It is ideal for warehouses with high order volumes, varied SKUs, and strict shipping deadlines. It ensures that picking activities are aligned with carrier schedules.

Pros

- Optimized use of resources and pickers time

- Better alignment with carrier pickups or shipping deadlines

- Flexible order grouping by product type, priority, destination, carrier, etc.

- Effective workload management in large warehouses

Cons

- Complex setup

- Need higher training and coordination

- Potential of order delays

- Inflexibility in responding to sudden order changes

Pick-to-Light / Voice Picking

Pick-to-light and voice picking are technology-assisted methods that uses lights or voice commands to guide pickers. The light indicators or voice help the pickers to go to the correct location. The picker picks the item and confirms it by pressing the button. The system integrates with warehouse management software for real-time tracking. This method is ideal for businesses who need faster fulfillment with higher accuracy

Pros

- Increased picking speed

- Less training time

- Lower picking errors

- Smooth scalability

- Minimize unnecessary walking

Cons

- High initial setup and hardware costs

- Not ideal for large or bulky items

- Less flexible if frequent changes in pick locations

Best Practices for Warehouse Picking Efficiency

You don’t always need big investments to make your warehouse picking process better. Sometimes, small changes can make a huge difference. Here are some proven best practices to boost efficiency and accuracy:

- Choose the Right Picking Method

Pick a strategy that fits your operation size and the types of orders you handle.

- Keep Inventory Well-Organized

Store fast-moving items close to packing areas and group related products together to cut down on travel time.

- Train and Cross Train Staff

Well-trained employees are faster and more accurate, while cross-training helps keep things running smoothly.

- Use Barcode Scanners

Barcode inventory system helps reduce mistakes and speed up the picking process.

- Cut Down on Travel Time

Plan efficient pick routes and keep your warehouse layout optimized for easy access.

- Leverage Technology

Use systems like C2W Inventory to simplify management and streamline tasks.

How to Measure the Efficiency of Your Order Picking Process

You never know how effective your warehouse picking process is unless you measure its efficiency. Plus, tracking performance also helps you make the right improvements.

Below are some of the key metrics to monitor and measure the efficiency of the order picking process:

Pick Rate (Lines Picked per Hour) – It measures how many individual items or lines an employee picks within an hour. It helps evaluate productivity per employee.

Order Accuracy Rate – It tracks the percentage of orders picked correctly without errors. It reflects operational efficiency and customer satisfaction.

Orders Picked per Labor Hour – It indicates the total number of orders completed for each hour of labor. It indicates overall labor efficiency.

Travel Time per Pick – It measures the average time spent moving between picks. It helps identify opportunities to reduce wasted motion and speed up the process.

Cost per Pick – It measures the total labor and resource expenses per order. It helps control operational costs.

Common Challenges with Warehouse Picking

(and How to Overcome Them)

Warehouse picking is essential, but it also comes with its own set of challenges. It is important to address these challenges to optimize the warehouse operations.

Here are some of the common challenges and how to overcome them:

CHALLENGES

SOLUTION

Human Error

Human mistakes can lead to wrong shipments and unhappy customers.

Reduce errors by implementing barcode scanning for verification and providing clear pick lists.

Poor Warehouse Layout

If the warehouse layout is inefficient, it can slow down picking and increase fatigue.

Reorganize your warehouse based on product movement analysis to ensure frequently picked items are easily accessible.

Inconsistent Processes

Inconsistent warehouse processes can cause confusion and mistakes.

Establish standardized picking procedures and provide comprehensive training to all employees to ensure everyone follows the same efficient methods.

Lack of Visibility

If there is no clear visibility of warehouse operations, it makes optimization difficult.

Implement a warehouse management system that offers real-time tracking and analytics. It will help you identify bottlenecks and improve efficiency.

Scaling Issues

Sometimes we pick cheap warehouse systems that may work now, but break at higher volumes.

Choose scalable picking processes and invest in adaptable tools and technologies that can handle increased demand as your business grows.

Improve Warehouse Picking Efficiency with a WMS

No matter which picking method you use or how your warehouse is organized, one of the most effective ways to boost accuracy and productivity is by using a Warehouse Management System (WMS).

A Warehouse Management System (WMS) is a software solution that provides an all-in-one platform to manage and control daily warehouse operations. A good WMS helps you:

✅ Generate optimized pick lists

✅ Track inventory levels in real-time

✅ Assign and monitor picking tasks

✅ Reduce errors through barcode scanning

✅ Analyze performance and identify areas for improvement

Regardless of whether you are running a small warehouse or expanding your operations, a WMS like C2W Inventory gives you the tools to run smarter, faster, and with fewer mistakes.

🔍 Want to see how it works? Learn more about C2W Inventory and start improving your picking process today.