What is Inventory Accuracy?

Inventory accuracy is the metric that reflects the differences between the actual inventory in the warehouse and the amount entered in the inventory record.

100% inventory accuracy means that the physical stock matches the inventory records. For example, if you have 980 units of products on the shelves, the same number of units are listed in the inventory record.

An accurate inventory makes it easy to manage the stocks and avoid situations of overstocking and stockouts. However, inventory accuracy is many times not accurate due to mismanagement, theft, or other reasons.

Importance of Inventory Accuracy

Did you know that retail operations in the U.S. have an inventory accuracy of 63%? A lack of proper inventory overview leads to ineffective replenishment schedules and other issues.

The below points will help better clarify the importance of inventory accuracy:

Efficient Operations:

Accurate inventory ensures efficient inventory operations. You can make better decisions about when to order inventory. This reduces the chances of overstocking or stockouts.

Better Customer Satisfaction:

Accurate inventory means that customers can access the products without facing limited stock or stockout situations. They can order whenever they want in the quantity of their choice. This leads to better customer satisfaction and loyalty.

Effective Budgeting and Forecasting:

Inventory accuracy makes it easy and effective to budget and forecast. The real-time, accurate view of inventory helps understand sales trends and plan inventory accordingly.

Less Losses:

When inventory accuracy minimizes the chances of overstocking and stockouts, losses also reduce significantly. Moreover, it eradicates the concerns of damage or theft of inventory.

In short, inventory accuracy is directly linked to streamlined operations and long-term business growth.

How to Calculate Inventory Accuracy

Calculating the inventory accuracy of your business, you have to follow the two steps process as follows:

Step 1. Physical Count

The first step is about the physical count. You should physically count all your inventory. This step is time-consuming, especially if you have a large inventory to manage. However, it is an essential step to know the exact accuracy of your inventory.

Step 2. Inventory Accuracy Rate Formula

Once you know the physical count of your inventory, you can calculate the inventory accuracy rate using the below formula:

Inventory accuracy rate = (Physical Inventory Count / Recorded Inventory Count) x 100

For example, if the recorded inventory count in your inventory management system is 500 units, but your physical inventory count is 478 units, then your inventory accurate rate is:

478/500 x 100 = 95.6%

This means that your inventory accuracy is 95.6%. This way, you can easily calculate the accuracy rate of your inventory.

Common Challenges Faced with Inventory Accuracy

Although it looks simple to achieve 100% inventory accuracy, the reality does not seem that straightforward.

Some of the common challenges businesses face with inventory accuracy are as follows:

Human Errors:

An incorrect data entry or miscounting can unintentionally compromise accuracy.

Seasonal Impacts:

Busy sales seasons like Christmas can impact your inventory management practices, as it may be difficult to keep track of stock movements.

Multiple Warehouses:

A business with multiple warehouses means a complex inventory system. If the products are located in multiple locations, extra efforts are required to handle stocks.

Outdated Inventory System:

An outdated inventory system can cause troubles, such as an inability to track stock in real-time, incorrect inventory counts, and more.

In short, many reasons can intentionally or unintentionally lower inventory accuracy.

6 Tips & Tricks to Improve Inventory Accuracy

The accuracy rate of inventory is increasable in different ways. Below, we have shortlisted a few top tips and tricks to elevate inventory accuracy:

Regular Cycle Counting

Cycle counting is a unique way of counting inventory. Instead of counting all the inventory at once, this process counts a small portion every day. It does not require halting your warehouse operations for inventory count. You can keep your business going and count the inventory on the sidelines.

This way, you can have regular physical counts of your inventory, compare them with the recorded count, and fix inaccuracies in a timely manner.Organize Warehouses

Many times, inventory inaccuracy occurs because the warehouse is not organized properly. Try to keep the warehouse well-organized, where items are grouped correctly and easily countable.

Leverage the Right Technology

With the boom of technological advancements, using manual tracking systems does not seem right. These methods make it hard to modify/adjust inventory records and require significant time.

The right approach is to use barcodes, which make it easy to update warehouse records with simple scans. There are now inventory management systems that can pair with barcode technology and help automate inventory operations.Read more: Manual vs Automated Inventory Management

Use Inventory Management Software

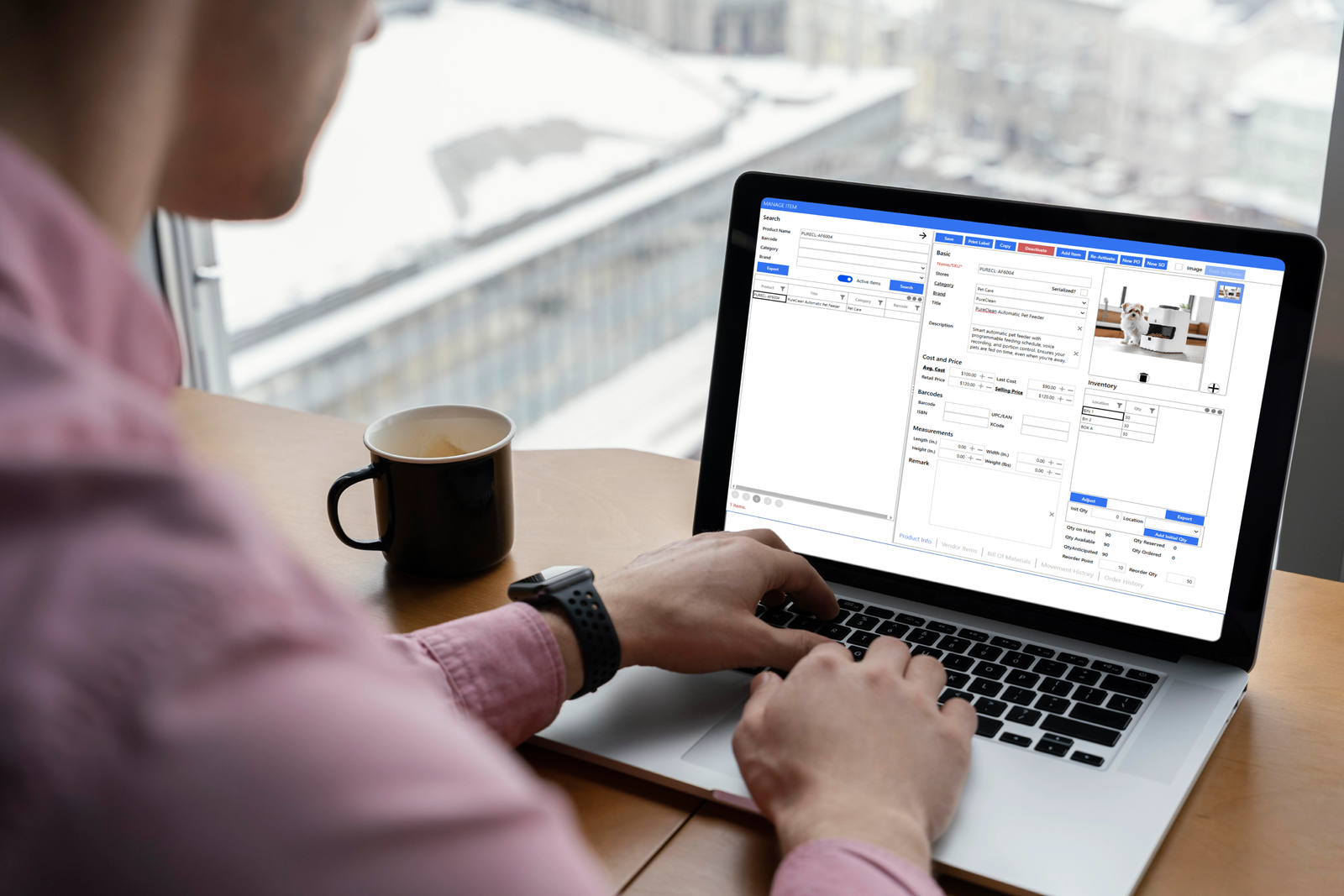

Using powerful inventory management software makes optimizing inventory accuracy easier. That’s where the C2W Inventory comes into action.

C2W Inventory is a modernized inventory management software that handles almost all inventory-related activities. With C2W, you can have:

- Centralized multi-warehouse management.

- Real-time inventory visibility and movement tracking.

- Visibility of the entire order fulfillment workflow.

- Automated alerts on reordering thresholds

- Mobile-based barcode scanning (Mobile SmartScan) paired with an inventory system.

Simply put, C2W Inventory offers a full-fledged inventory management system that ensures that all stock ins and outs are recorded autonomously and with high accuracy. Therefore, it is recommended that you deploy C2W Inventory and optimize your inventory management and accuracy.

Staff Training

Since human error is one reason for inventory inaccuracy, it can be minimized by training the staff. Proper training will increase the staff’s efficiency in data entry, stock counting, and other inventory management elements.

Outsource Inventory Management

If you are running a large business with multiple warehouses and products, you can outsource inventory management (storage and shipping operations). Outsourcing will help you save time and internal resources in managing inventory while having a reliable third-party team handling inventory tracking and management.

Conclusion – Use C2W Inventory to Modernize Inventory Management and Lift Up Inventory Accuracy

Inventory accuracy is a key indicator of how well a business is monitoring its inventory. An accurate inventory lowers stock disruptions and increases customer satisfaction, while an inaccurate inventory leads to stockouts/overstocking and lost sales.

Above, we have discussed multiple tips and tricks to improve inventory accuracy. Of all of them, the C2W Inventory is one of the must-follow tips for having the best low-cost and modernized approach to managing inventory. So, why struggle more with inventory inaccuracies? Try out C2W Inventory right away and visualize its impact on your business today.