Supply chains are under constant pressure to move faster, operate smarter, and deliver more efficiently. Manual workflows that once relied on spreadsheets, phone calls, and handwritten orders are no longer sustainable. That’s where supply chain automation is filling the gap.

Supply chain automation is about using technology to streamline and automate processes across the entire supply network, including procurement, inventory management, order fulfillment, and delivery. It replaces repetitive manual tasks with intelligent systems that can track, analyze, and execute operations in real time.

According to a McKinsey & Company report, organizations that invest in supply chain automation experience lower operational costs of up to 30% and achieve higher profits than the average.

In this guide, we will learn how supply chain automation works, the key technologies driving it, and the tangible benefits it delivers across industries.

Key Components of Supply Chain Automation

Supply chain automation doesn’t start with robots or complex AI systems. It begins with simple and practical tools that streamline everyday inventory management challenges. The goal is to build a connected network where information flows seamlessly.

At its core, an automated supply chain relies on several key components that work together to improve visibility, accuracy, and speed:

- Inventory Management Software: Centralized inventory systems are the backbone of automation. They provide real-time updates on stock levels, product locations, and reorder points. For example, C2W Inventory is an intelligent inventory management software that offers real-time stock tracking, barcode label generation, reorder alerts, order insights, and more.

- Barcode and RFID Technology: Barcodes and RFID tag systems eliminate the need for manual data entry by automatically tracking items as they move through the supply chain. This technology ensures that every product scan updates the system instantly, improving traceability and reducing errors during receiving, picking, and shipping.

- Automated Order Processing: Order fulfillment can be one of the most time-consuming parts of the supply chain. Automation software connects e-commerce platforms, warehouses, and shipping partners, ensuring that warehouse picking, packaging, and dispatching occur with minimal delay and maximum accuracy.

- Electronic Data Interchange (EDI): EDI enables companies to exchange documents like purchase orders, invoices, and shipment details electronically, replacing traditional paper-based communication. This not only speeds up transactions but also reduces administrative costs and human errors.

- AI and Machine Learning Systems: Artificial intelligence enhances automation by providing predictive insights, such as anticipating demand spikes or identifying supply chain risks. Machine learning models continuously analyze historical data to recommend smarter purchasing and production decisions.

- IoT (Internet of Things) Sensors: IoT sensors collect real-time data on shipment conditions, location, and equipment performance. For industries dealing with temperature-sensitive goods or complex logistics, these sensors help maintain quality and visibility throughout the journey.

When these components work in harmony, the result is a connected and data-driven supply chain that operates with precision and agility. Businesses can detect bottlenecks before they occur, fulfill orders faster, and optimize inventory management with changing market demands

6 Benefits of Automating Supply Chain Operations

Every link in a supply chain is connected, so when a delay or error occurs in one stage, it can ripple across the entire operation. Automation streamlines workflows and enhances coordination between teams and systems, which minimizes disruptions. Below are the key benefits you can get from automating supply chain operations:

1. Enhanced Accuracy and Reduced Errors

Manual data entry and paper-based tracking often lead to miscounts, misplaced items, or incorrect shipments. Automation tools eliminate these risks by capturing and processing data instantly. Whether it’s barcode scanning or automated invoicing, businesses experience fewer mistakes and more reliable information. Overall, this improves both operational efficiency and customer satisfaction.

2. Real-Time Visibility and Tracking

Automation gives managers a real-time view of inventory levels, order statuses, and shipment progress. For example, C2W Inventory offers a comprehensive reporting dashboard with views on sales orders, purchase orders, inventory insights, and more.

Live dashboards and analytics empower decision-makers to identify bottlenecks before they occur and adjust workflows on the fly. This transparency not only supports faster decision-making but also builds stronger collaboration between suppliers, distributors, and logistics partners.

3. Faster Order Fulfillment

Automated systems speed up everything from picking and packing to shipping. Orders are processed as soon as they are received, and data syncs instantly between your e-commerce, warehouse, and logistics platforms. The result is quicker turnaround times, fewer backlogs, and happier customers.

4. Cost Efficiency and Scalability

Supply chain automation reduces human error and repetitive labor, which cuts operational costs significantly. As mentioned above, McKinsey estimates that companies can achieve up to 30% lower operational expenses with the right automation strategy. Moreover, as order volumes grow, these systems easily scale to handle additional workloads without the need for proportional staffing increases.

5. Better Decision-Making Through Data

Automation tools collect valuable performance data across multiple touchpoints, including inventory turnover rates, supplier reliability, fulfillment speed, and more. These insights help leaders make proactive decisions, such as when to reorder, which vendors to prioritize, or how to optimize logistics routes.

6. Improved Customer Experience

At the end of the chain is the customer, and automation ensures they receive orders accurately and on time. With faster processing, real-time order tracking, and fewer delays, businesses can deliver a more reliable and transparent experience that builds trust and loyalty.

Challenges with Supply Chain Automation

Supply chain automation is essential and undeniable, but the transition from traditional processes to fully automated systems isn’t always easy. Businesses often face a mix of technical and financial challenges that can slow down the implementation.

High Initial Costs

One of the most common obstacles is the upfront investment. Implementing automation requires purchasing new software, upgrading hardware like barcode scanners or IoT sensors, and possibly restructuring workflows. Smaller companies may struggle to justify the cost before seeing measurable results. However, experts note that these expenses are typically offset by long-term savings in labor, time, and error reduction.

Integration with Legacy Systems

Many organizations still rely on outdated software that doesn’t easily connect with modern automation tools. Poor integration can lead to inconsistent data, duplicate records, or workflow interruptions. To avoid this, businesses need a clear integration plan and, where possible, cloud-based solutions that support cross-platform communication and API compatibility.

Employee Resistance and Training Gaps

Introducing automation often changes how teams work, which can cause resistance or anxiety among employees. Some may fear job loss or feel overwhelmed by unfamiliar technologies. Effective training programs, clear communication, and gradual implementation help employees adapt and see automation as a tool that supports their productivity rather than replaces them.

Poor Implementation Planning

Even the best technology can fail if rolled out without a strategy. Rushing the transition, skipping testing phases, or underestimating workflow adjustments can result in downtime and operational chaos. A phased approach that starts with small and high-impact areas before scaling can ensure smoother adoption and measurable progress.

Maintenance and Data Security Concerns

Automation systems require ongoing maintenance, software updates, and cybersecurity measures. Since these systems often handle sensitive business and customer data, the risk of cyberattacks or data breaches must be taken seriously. Partnering with reputable software providers and establishing robust security protocols are crucial for long-term success.

Change Management Complexity

Beyond technology, automation introduces organizational change. Leadership must align departments, redefine roles, and foster a culture of continuous improvement. Without proper change management, even the most advanced automation system can face pushback and underperformance.

How to Begin Supply Chain Automation?

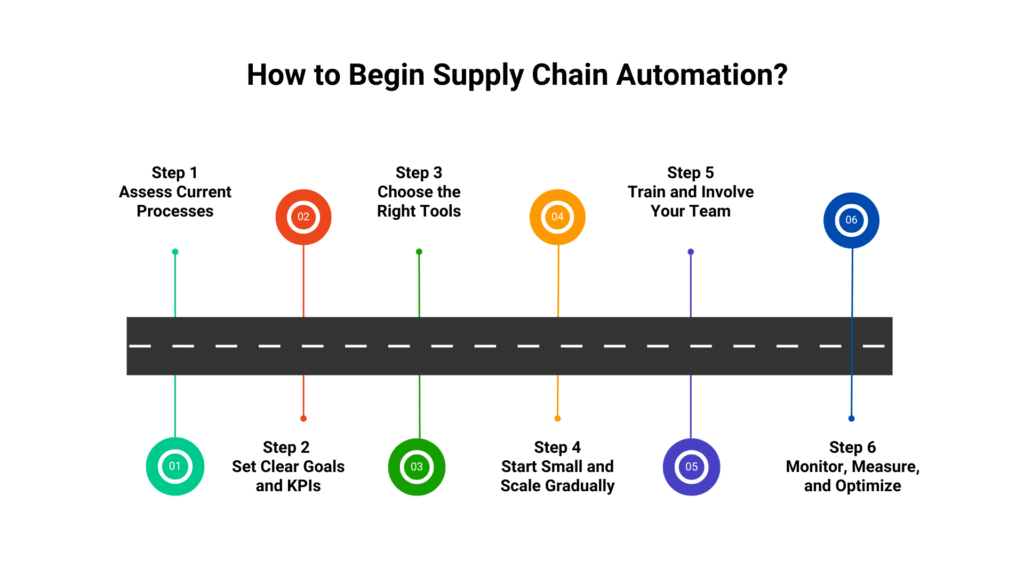

Implementing supply chain automation doesn’t have to be an all-or-nothing transformation. In fact, the most successful companies begin small and automate one process at a time. They learn from each step and gradually expand across their operations. The key is to identify where automation can make the most immediate impact and scale from there.

Follow the steps below to start automating your supply chain:

Step 1. Assess Current Processes

Start by mapping your existing supply chain workflows from procurement to delivery. Identify areas that are slow, error-prone, or heavily dependent on manual labor. These are prime candidates for automation. For example, if your team spends hours each week tracking stock manually, implementing an inventory management system should be your first priority.

Step 2. Set Clear Goals and KPIs

Before adopting new tools, define what success looks like. Do you want to reduce lead times, lower labor costs, or improve order accuracy? Establish measurable key performance indicators (KPIs) such as fulfillment speed, inventory turnover rate, or order error percentage. These benchmarks will help you evaluate automation’s effectiveness over time.

Step 3. Choose the Right Tools

Select automation solutions that align with your operational needs and budget. Start with foundational software like inventory management systems, automated purchase order generation, and barcode tracking.

For growing businesses, C2W Inventory offers scalable solutions that integrate easily with accounting, e-commerce, and logistics systems, ensuring real-time visibility without complex setup.

Step 4. Start Small and Scale Gradually

Rather than automating everything at once, begin with one function, such as stock tracking or order fulfillment, and test how automation improves performance. Once you achieve consistent results, extend automation to related processes like supplier communication, invoicing, or shipment tracking. This phased approach minimizes risk and helps teams adapt more comfortably.

Step 5. Train and Involve Your Team

Technology alone can’t deliver success. Your people must be part of the process. Provide hands-on training sessions and explain how automation will simplify their workload and reduce repetitive tasks. Encouraging feedback and participation ensures smoother adoption and stronger team alignment.

Step 6. Monitor, Measure, and Optimize

Automation isn’t a one-time setup; it requires ongoing analysis. Use dashboards and analytics tools to monitor performance, track KPIs, and identify improvement areas. Regularly evaluate how well your systems are integrating and make adjustments as your business grows or processes evolve.

Future Trends of Automation in Supply Chain Management

The next wave of supply chain automation is shifting from efficiency to intelligence. Instead of simply speeding up workflows, future systems will think, learn, and adapt. The advancements in AI, robotics, and blockchain will make tomorrow’s supply chains anticipate disruptions, self-correct errors, and make data-driven decisions instantly.

Some of the key trends to watch include:

- AI and Machine Learning: Predict demand, optimize routes, and detect disruptions before they occur.

- IoT and Smart Sensors: Enable real-time tracking of goods, temperature, and equipment performance.

- Robotic Process Automation (RPA): Streamline repetitive tasks like invoicing, data entry, and order validation.

- Blockchain Integration: Improve transparency, traceability, and trust across suppliers and partners.

- Cloud-Based Platforms: Enhance collaboration and scalability through unified, accessible data systems.

As these technologies mature, supply chains will evolve from reactive systems into intelligent ecosystems that anticipate, adapt, and optimize with minimal human involvement.

Conclusion

Supply chain automation has become the backbone of modern business efficiency. The adoption of smart tools and data-driven systems is helping companies cut costs, minimize errors, and enhance agility across operations. Therefore, it’s time to streamline your inventory workflows and gain real-time visibility. Start automating today with C2W Inventory and gradually transform your supply chain into a fully connected and intelligent ecosystem.