Inventory Challenges for 3PL and Fulfillment Companies

Third-party logistics providers and fulfillment companies operate in fast-moving environments where accuracy, speed, and transparency matter every day. Unlike traditional warehouses, 3PLs manage inventory for multiple clients, each with different products, order volumes, and expectations. In fact, nearly 60% of 3PL warehouses are operating at over 90% capacity, while another 28% operate at 80%-89% capacity, which adds strain to inventory handling and space optimization.

As fulfillment operations grow, inventory challenges for 3PL and fulfillment companies become more complex. Without strong inventory control and visibility, small issues can quickly turn into missed shipments, reporting problems, and unhappy clients.

Managing Inventory for Multiple Clients

Handling inventory for multiple clients requires clear separation, accurate tracking, and reliable ownership records.

Each client may have its own SKUs, storage rules, and service requirements. When inventory is not clearly organized and tracked by the client, mistakes such as mixed inventory, incorrect shipments, or billing disputes become more likely. For 3PLs operating across multiple warehouses, these challenges are even greater, especially when inventory is split between locations. This is why strong multi-location inventory management becomes essential as fulfillment operations scale.

Inventory Challenges in E-commerce Fulfillment

E-commerce fulfillment is driven by speed, volume, and constant order flow.

Orders are often small but frequent, and inventory moves quickly throughout the day. High order volume, peak seasons, and tight shipping deadlines increase the risk of picking errors and inaccurate stock levels. When inventory records fall behind real activity, businesses may oversell products or experience unexpected stockouts.

Maintaining real-time inventory accuracy is critical to keeping e-commerce fulfillment running smoothly.

Inventory Challenges in B2B Distribution

B2B distribution focuses more on bulk orders, scheduled shipments, and long-term client relationships.

Although order frequency may be lower than e-commerce, accuracy remains just as important. Large shipments often involve significant quantities, and even small errors can cause delays, disputes, or downstream production issues. Reliable inventory data helps B2B clients plan ahead and reduces operational friction.

Tracking Inventory Across Multiple Locations

Many 3PLs operate more than one warehouse or fulfillment center.

Inventory may be spread across locations based on shipping zones, storage capacity, or client demand. Without centralized visibility, one location may run out of stock while another holds excess inventory for the same client. This often leads to unnecessary transfers and delayed fulfillment, highlighting the importance of effective multi-location inventory tracking.

Keeping Inventory Records Accurate as Items Move

Fulfillment operations involve constant inventory movement throughout the day.

Inventory is received, stored, picked, transferred, and shipped at a rapid pace. If these movements are not recorded immediately, inventory data quickly becomes unreliable. Manual processes make this problem worse, especially in high-volume fulfillment environments.

Barcode scanning plays a key role in reducing these errors by capturing inventory movements as they happen.

Client Inventory Segmentation and Billing Accuracy

Clear inventory separation directly affects reporting accuracy and client billing.

For 3PLs, inventory accuracy is closely tied to billing and client trust. Storage fees, handling charges, and fulfillment costs are often calculated based on inventory quantities and movement. When inventory is not clearly segmented by client or accurately tracked, billing disputes become more common.

Maintaining precise inventory records helps ensure that clients are billed correctly and consistently. This transparency not only reduces disputes but also strengthens long-term client relationships.

Scaling 3PL Operations Without Losing Control

Growth introduces more clients, more SKUs, and more operational complexity.

As 3PLs grow, inventory challenges multiply. Adding new clients, expanding warehouse space, or opening additional locations increases the need for consistent inventory processes. Without strong systems in place, growth can quickly lead to data gaps and operational strain.

Focusing on visibility, accuracy, and standardized workflows allows fulfillment companies to scale while maintaining control over inventory operations.

Read more: How To Optimize Inventory Management in eCommerce: 7 Tips for Startups

Meeting Client Reporting Expectations

3PL clients expect visibility into their inventory at all times.

Clients rely on accurate reports to understand current stock levels, past movement, and future replenishment needs. When inventory data is delayed or inconsistent, reporting becomes time-consuming and unreliable. Clear, accurate inventory records make reporting easier and build trust with clients.

Using Inventory Software in 3PL Operations

As fulfillment operations scale, many 3PLs rely on inventory management software to maintain control and visibility.

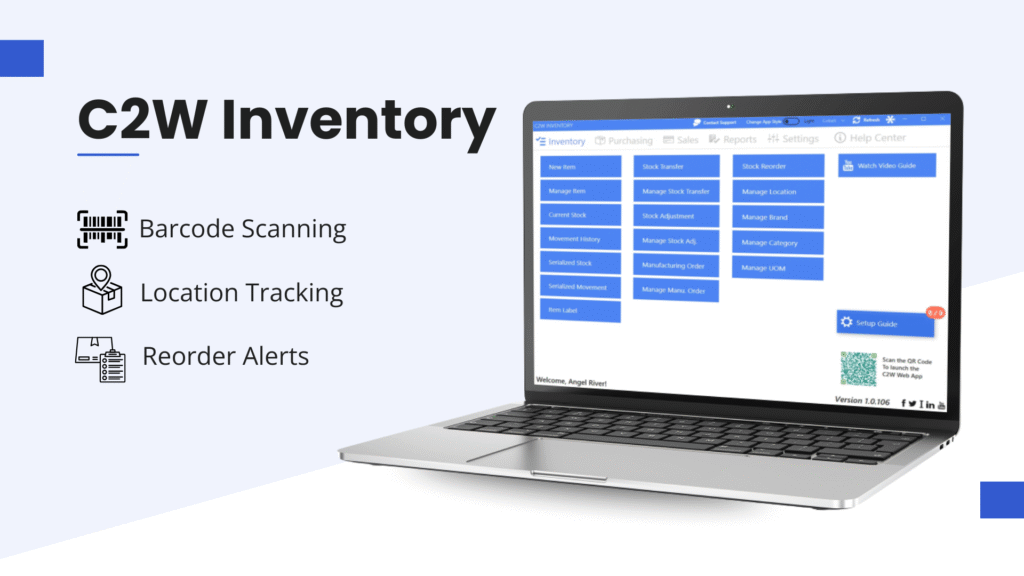

Systems like C2W Inventory are designed to support 3PL environments by tracking inventory by client, location, and status in one centralized system. A key strength of C2W Inventory is its built-in barcode scanning, which allows teams to scan inventory during receiving, picking, transfers, and adjustments using Android devices or scanners. This helps ensure inventory records stay accurate as items move through the warehouse.

C2W Inventory also allows fulfillment teams to set reorder points and reorder quantities for client inventory control. When stock reaches a defined threshold, the system can trigger alerts or send email notifications, helping 3PLs and their clients plan replenishment before shortages occur.

Wrapping Up: Build a More Reliable Fulfillment Operation

Inventory challenges increase as fulfillment volume and complexity grow.

By improving visibility, using barcode-driven processes, and managing inventory across locations in a centralized system, fulfillment companies can reduce errors, improve client confidence, and scale more effectively. Addressing these challenges early creates a stronger foundation for long-term growth and reliability.