Inventory management is a need of every business. Ineffective inventory management leads to stockouts/overstocking, missed sales opportunities, and higher operational costs. In fact, 34% of businesses today struggle with delayed shipments or unavailable products.

Considering the technological advancements, there are now two ways of inventory management, i.e., manual inventory management or automated inventory management. The formal involves using spreadsheets, while the latter involves using inventory management software. So, which management approach is right for your business?

In this guide, we will define both manual and automated inventory management systems and talk about their key differences. Afterward, we will highlight why automated inventory management is becoming essential for modern businesses. So, let’s head right to it!

What is Manual Inventory Management?

Manual inventory management refers to the manual system of monitoring, tracking, and managing inventory levels. It is also referred to as a physical or paper-based inventory management system.

In manual inventory management, a person usually uses a spreadsheet to record and track inventory levels, orders, and sales. Simply put, there is a dedicated person or group of individuals who have to manually update all the activities around the inventory by hand.

A typical workflow of manual inventory management is as follows:

- The person counts the new inventory received and updates the stock levels accordingly.

- After every sale, the person records the sale and updates the inventory levels.

- The person regularly monitors inventory levels to avoid situations of stockouts or overstocking.

- When reordering stock, the person checks the existing inventory levels, predicts future demand, and places orders accordingly.

- The person manually generates inventory reports for higher management to analyze and make decisions.

In short, a manual inventory management system revolves around the designated person who is responsible for keeping the inventory data intact and up to date.

Benefits of Manual Inventory Management System

- Best suited for small businesses managing only a few dozen products.

- Free system that can operate on a single Excel spreadsheet.

- No need for training or software configuration.

- No dependence on the internet, making it more secure from cyber threats.

Drawbacks of Manual Inventory Management System

- Vulnerable to human error. A small mistake in inventory levels can lead to an overstock/stockout situation.

- Unmanageable as the business inventory size grows.

- Time-consuming way to record, monitor, and manage inventory.

- Difficult to centrally manage inventory for multiple locations.

What is Automated Inventory Management?

Automated inventory management refers to an automated system for managing, tracking, and updating inventory in real-time. It involves the use of inventory management software that helps effectively monitor stock levels, record sales automatically, predict demand, and more. It can also automatically generate alerts for low stocks or even provide comprehensive reports/analytics on inventory performance.

An automated inventory management system also involves QR codes and barcodes for quick updates to inventory data on the system. A typical workflow of an automated inventory management system is as follows:

- New inventory is scanned, and the system instantly updates stock levels.

- After each sale, the system records the details and adjusts the stock levels automatically.

- The system regularly checks inventory levels and sends low-stock alerts when needed.

- The system automatically creates purchase orders based on set thresholds.

- The system can generate detailed reports on inventory and sales with just a few clicks.

In short, an automated inventory management system eliminates the manpower required to manage inventory and lets the automated system handle all the activities proficiently.

Benefits of Automated Inventory Management System

- Instant, up-to-date, and real-time information on inventory levels.

- Automated stock management during restocking or sales processes.

- No human errors.

- Timely alerts on low stock levels.

- Automated reordering of stocks

- Click-based reports on inventory levels.

- Better forecasting.

- Easy scalability as the business grows.

- Centralized inventory management across multiple warehouses.

- Reduced risk of stockouts or overstocking.

Drawbacks of Automated Inventory Management System

- Requires time to configure and integrate with your inventory.

- Require paying a regular subscription fee for the software.

- Learning curve.

- Timely maintenance and update to the system.

Manual vs Automated Inventory Management System: 8 Key Differences

Looking at the above thorough overview of manual and automated inventory management systems, it is evident that both have their benefits and drawbacks. However, an automated management system offers superior capabilities than a manual one.

Here are some of the key differences between manual vs automated inventory management systems:

⦁ Efficiency

Manual inventory management is not an efficient way of managing inventory. It requires significant time to count, manage, and monitor inventory. So, it is only suitable for businesses with a small inventory to manage.

Automated inventory management is an efficient way to handle inventory no matter the business size. It can automatically adjust the inventory levels with new inventory or sales and provide a comprehensive dashboard to view inventory stats right away.

⦁ Accuracy

Manual inventory management is highly vulnerable to human errors. As mentioned above, a single numeric mistake in the total inventory count can lead to major operational disruption.

Automated inventory management is more accurate. The real-time and autonomous way of inventory management and monitoring eliminates human errors. This lowers the risk of stockouts or overstocking.

⦁ Cost

Manual inventory management is possible without spending a single penny. You just need a spreadsheet and a computer to manage the inventory levels. However, the possibility of human errors and required manpower can increase operational costs.

Automated inventory management requires an upfront cost to purchase/subscribe to the inventory management software and configure the setup. Afterward, you have to pay the monthly subscription charges if you are using subscription-based software. However, this cost is compensated in the long run due to the operational efficiency it brings.

⦁ Real-time Updates

Manual inventory management cannot offer real-time updates on inventory levels. This is because all transactions and inventory activities must be recorded and updated manually, which can lead to delays.

Automated inventory management can offer real-time updates at any time you want. All you have to do is visit the software dashboard to see the current inventory level, sales statistics, and much more.

⦁ Scalability

Manual inventory management isn’t friendly when it comes to scalability. Once your business starts to grow, your inventory and sales will increase. So, the manual spreadsheet-based approach will become more complex and vulnerable to errors.

Automated inventory management can scale as your business grows. Due to automated operations, it can easily record and process more inventory-related activities. Furthermore, it provides a centralized way to manage multiple locations.

⦁ Integration

Manual inventory management cannot integrate with different platforms you use for selling inventory, such as Amazon, Shopify, etc.

Automated inventory management can integrate with essential business tools and selling platforms. It can intelligently record sales activities across different platforms and keep inventory levels up to date.

⦁ Stock Alerts

Failure of inventory tracking is causing a negative impact on 62% of business finances. Manual inventory management does not involve real-time stock alerts. You will be checking stock levels periodically, which increases the risk of stockouts or overstocking. Furthermore, it can also lead to missed sales opportunities and more operation costs.

Automated inventory management system offers built-in stock alert functionality. It allows you to specify the minimum and maximum stock levels for each item. When inventory levels reach these predefined thresholds, the system automatically sends alerts. This way, you can keep your stock levels well-maintained and never miss the sales opportunities.

⦁ Reporting

Manual inventory management requires manual efforts to create reports. You have to gather insights about the current inventory data, sales statistics, and other records. Afterward, you have to compile them into a reader-friendly report. This whole process requires significant time.

Automated inventory management software offers a click-based approach to getting reports. It involves a built-in functionality to generate reports, which includes all insights about inventory levels, sales, and others. This helps you quickly look into their sales performance and make decisions accordingly.

Why is an Automated Inventory Management System a Must for Businesses in 2024?

The comparison between manual vs automated inventory management systems clearly shows that manual systems have no long-term benefits. They should only be considered if you are running a small business.

However, an automated inventory management system is best for all types of businesses, including startups, small-to-midsize businesses, and enterprises. It not only automates inventory management but also ensures smooth inventory handling as your business grows.

With automated inventory management, you get:

- 24/7 inventory updates

- Centralized inventory management for multiple locations

- Auto inventory readjustments with sales

- Timely alerts

- Better inventory forecasts

- Easy scalability

- More sales and higher customer satisfaction

- Reports and analytics

Considering the competitive business world and customers’ emerging demands, the above offering with an automated inventory management system is a must to survive. Therefore, set aside the decades-old manual management approach and opt for an automated and modernized inventory management system.

C2W Inventory – The Ideal Automated Inventory Management Software You Need

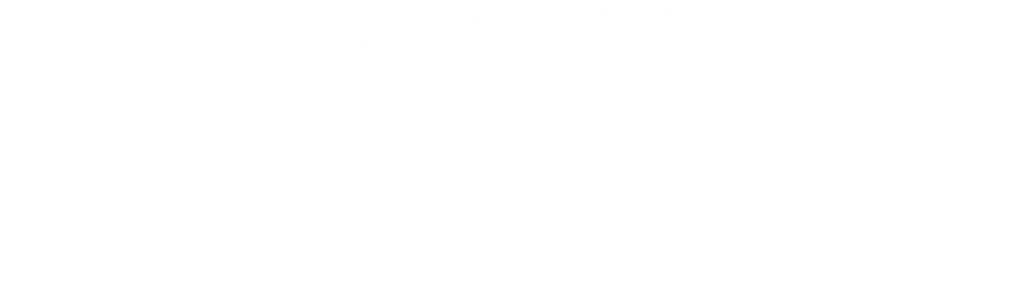

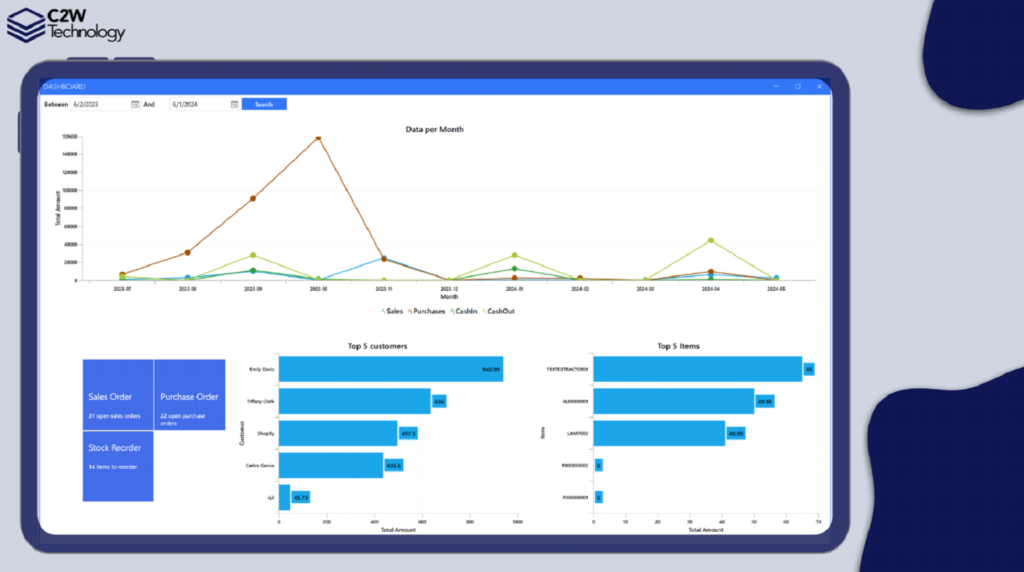

C2W Inventory is a modernized automated inventory management software that provides an all-in-one platform to handle all inventory-related activities. It offers an intuitive, click-based interface that is easy to configure and use without any learning curve.

With C2W Inventory, you get:

- Centralized system to manage single or multiple warehouses.

- Holistic view of all inventory levels of your products.

- Real-time inventory visibility for instant tracking of stock levels and monitoring movements.

- Streamlined order fulfillment workflow for faster order fulfillment and improved customer satisfaction.

- Customizable reorder point alerts for every product to avoid stockout situations.

- Mobile SmartScan system to scan, track, and manage inventory with real-time barcode scanning.

- Comprehensive inventory reports that highlight top-performing products, sales trends, and more.

- Integration with Shopify, Shippo, Amazon Services, APC, and more.

In short, C2W Inventory provides a one-stop automated inventory management system that manages inventory, handles sales and purchases, and provides comprehensive reports.

To wrap up, it’s time for action. Try a free trial of C2W Inventory and automate your inventory management starting today.