Efficient inventory management is essential to fulfilling customers’ demands on time. In the growing competitive era, businesses must exceed customer expectations by delivering top-notch products and keeping their inventory current and active. However, it is not unusual for businesses to struggle with inventory management challenges.

In the U.S., inventory accuracy is 63% in retail operations, which means that there are significant chances of stockouts/overstocking and negative customer experiences. Therefore, this blog will highlight some of the top inventory management challenges and how to solve them.

So, if you are a new startup or want to optimize your inventory management, follow along to learn about and address common inventory management challenges.

10 Top Inventory Management Challenges and Their Solutions

Inventory management is a tedious task. Inefficient inventory management can impact all your business’s processes. Here are the 10 top inventory management challenges you should be aware of to tackle them professionally:

1. Lack of Real-time Inventory Visibility

Many businesses lack real-time inventory visibility. They are unaware of their current inventory levels and where their goods are. This lack of visibility can lead to delays in shipment and stock delivery, as well as higher shipping costs.

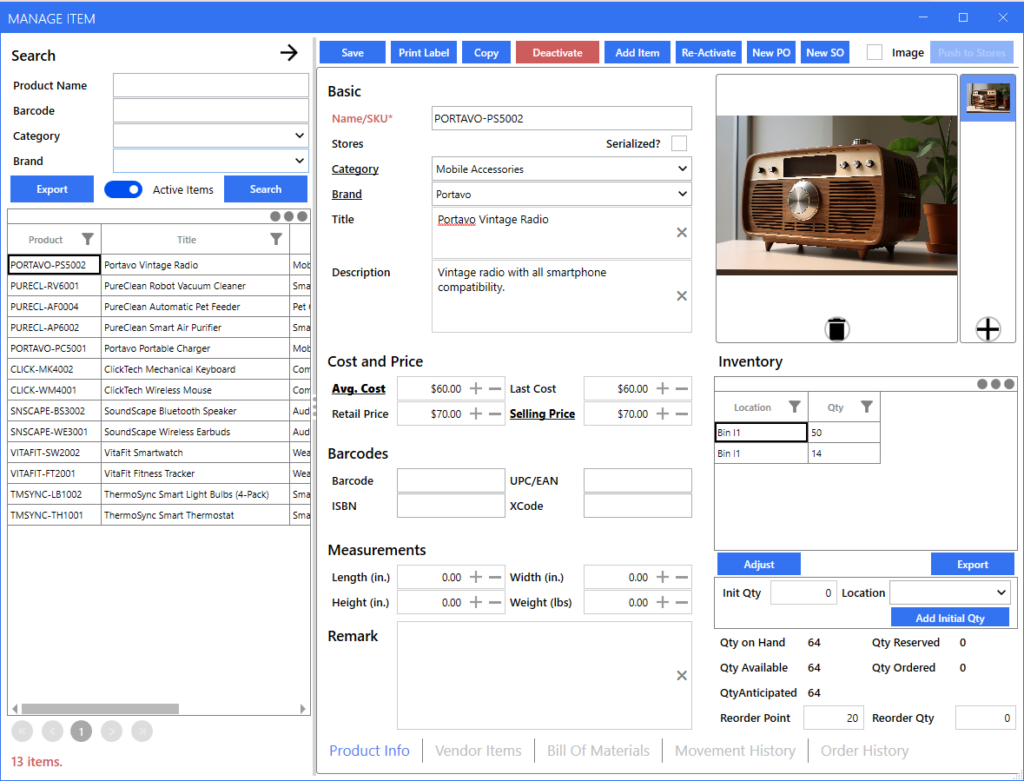

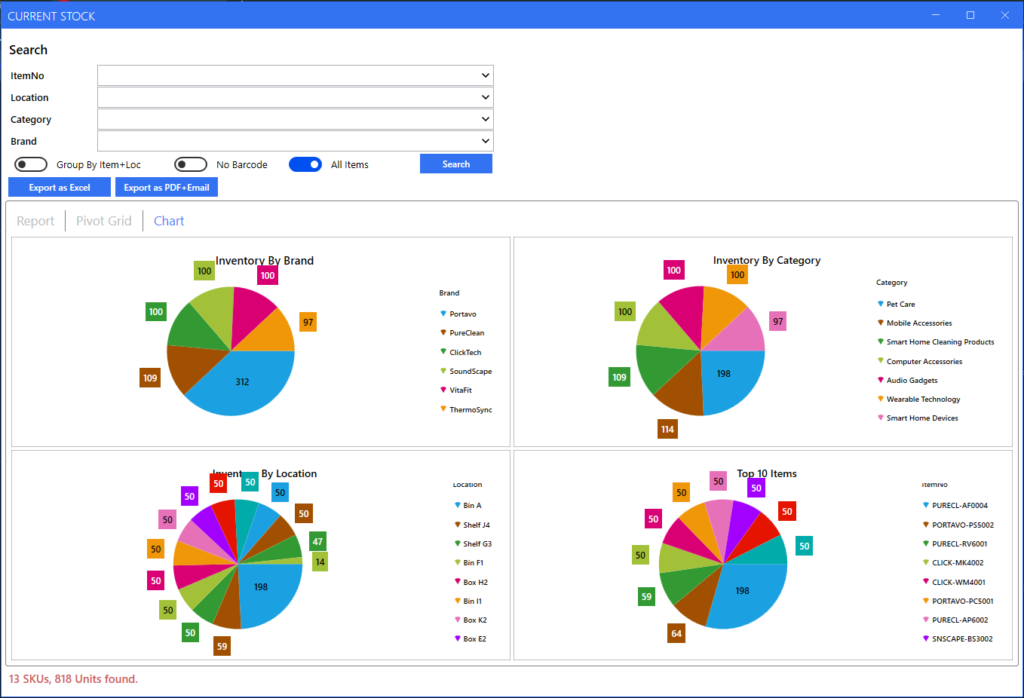

Solution: The best solution is to use a real-time inventory visibility system, such as C2W Inventory. C2W Inventory offers real-time visibility of your stocks and updates them instantly. It provides 360-degree product details, real-time stock updates, exact quantities information in all locations, order history logs, and more. This way, you can have comprehensive inventory visibility in real-time.

2. Overstocking or Stockouts

Overstocking or stockouts are common inventory management challenges businesses need to tackle. According to one study, inventory distortion causes around $818 billion annually in losses globally, 44% of which are due to overstocks and 52% to stockouts.

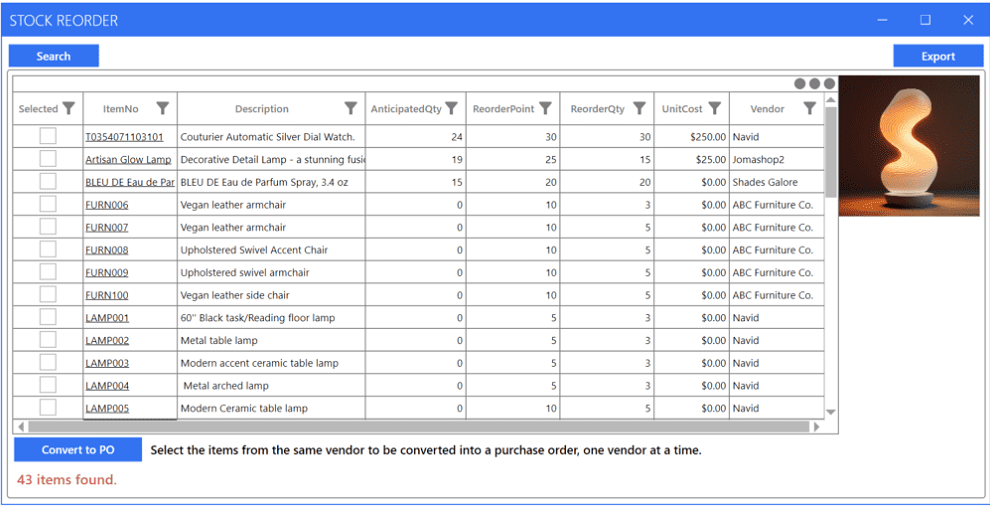

Solution: Overstocking or stockouts are easily addressable if you get real-time stock alerts. For instance, C2W Inventory offers centralized inventory control, where you can manually look at your current inventory level or get real-time stock updates autonomously. Furthermore, it can send reorder alerts or initiate automated reordering once the stock levels have fallen below the specified threshold. This way, you can ensure that you never get into the issues of overstocking or stockouts.

3. Multiple Warehouse Management

For businesses that have multiple warehouses, managing inventory across different locations is challenging. They need efficient coordination and tracking to ensure that the right products are present in the right place.

Solution: The easiest way to manage multiple warehouses is to use inventory management software that provides centralized management. For example, C2W Inventory offers a centralized system to manage inventory across multiple warehouses. You get a holistic view of your stock and can easily move and organize them across warehouses.

4. Poor Demand Forecasting

Businesses need to project accurate demand forecasts to manage the inventory accordingly. However, many businesses struggle with poor demand forecasts. They either face issues of low stock or overstocking just because they couldn’t forecast the demand accurately.

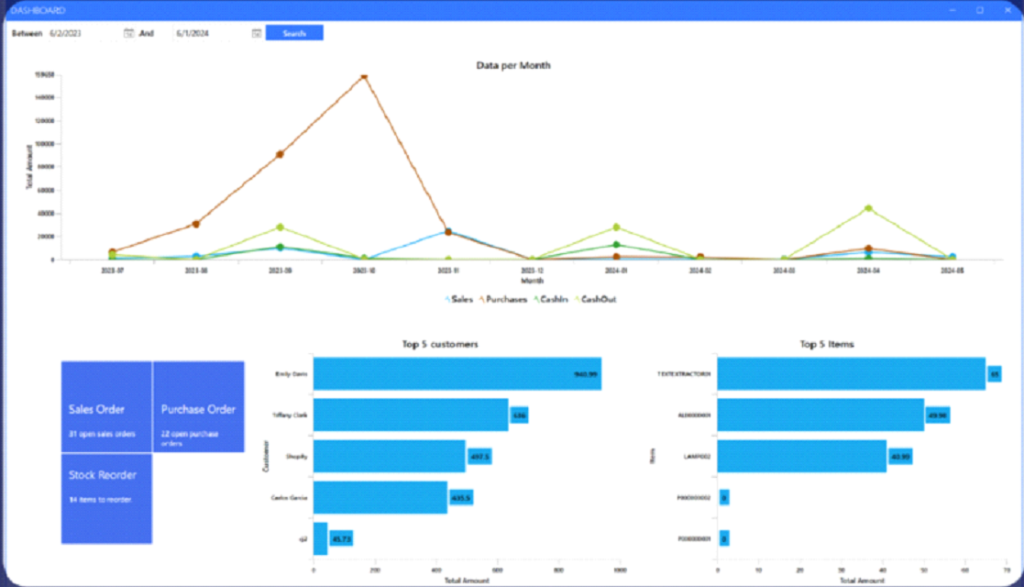

Solution: Advanced analytics and forecasting tools can improve demand forecasts. For example, the C2W Inventory tool provides comprehensive inventory reports that reflect top-performing items, sales trends, and other useful insights. This information helps forecast demand better and make data-driven decisions.

5. Inefficient Ordering and Tracking System

Another of the top inventory management challenges is an inefficient ordering and tracking system. This leads to delays in delivery, increased operational costs, and other issues.

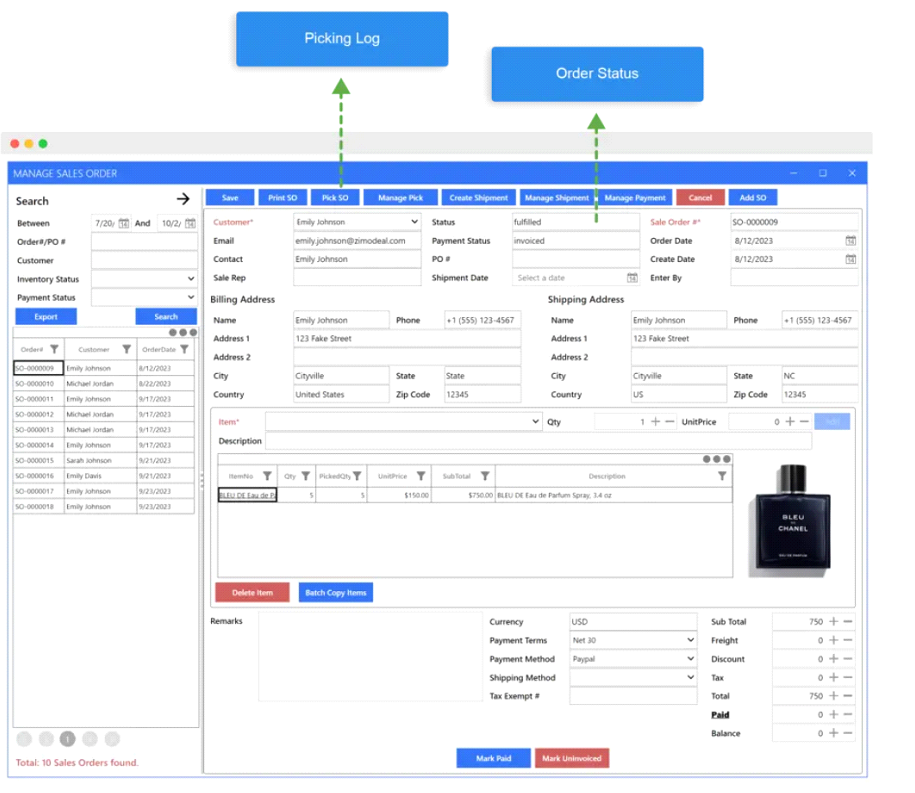

Solution: You should automate the ordering and tracking processes. C2W Inventory helps to create automated workflows for order processing, which leads to fewer errors and accurate deliveries. Moreover, it ensures effective customer management by consolidating customer data, payment records, and order history. You also get comprehensive sales analytics to make strategic decisions.

6. Redundant Manual Procedures

Some businesses manage inventory using manual procedures. They may use spreadsheets to record stock levels, orders, and sales. Manual procedures are not only time-consuming, but they are more vulnerable to errors. Moreover, they can slow down the order fulfillment process.

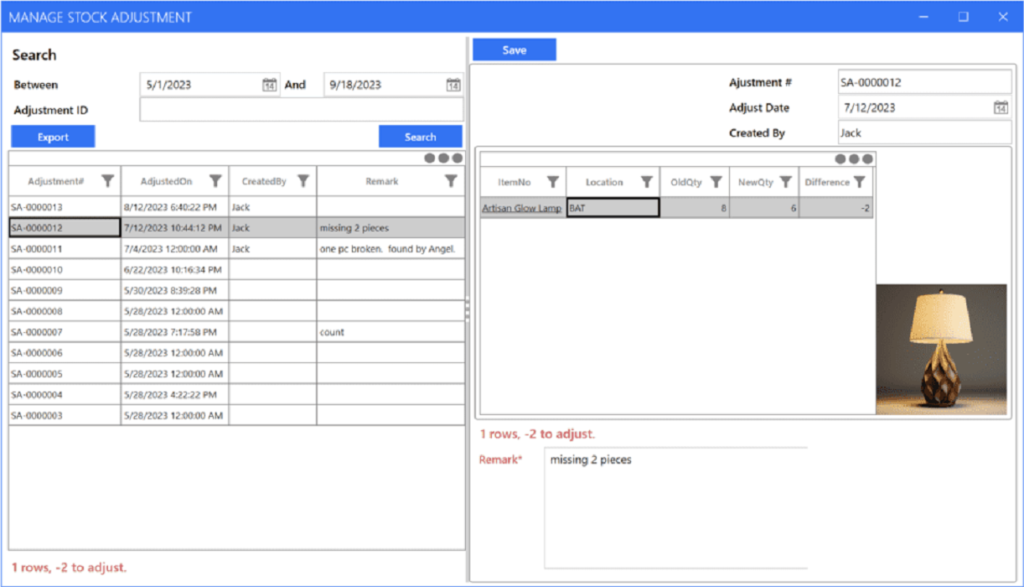

Solution: You should eliminate manual procedures and convert them into automated ones. This is possible by investing in modern technology solutions, like C2W Inventory. C2W Inventory offers an automated inventory management system where you can monitor stock levels, record sales, send stock alerts, predict demand, and more.

7. Not Integrated Sales Channels

Some businesses sell their products through multiple channels, such as Shopify, Amazon, physical stores, and others. If the sales channels are not integrated, managing inventory across those channels becomes a mess. It increases the challenge of stockouts, overselling, and customer dissatisfaction.

Solution: The best solution for this challenge is to integrate sales channels through a unified system. For example, C2W Inventory can integrate with different sales platforms, such as Shopify, Shippo, Amazon Services, etc. This way, you can have centralized control of your inventory, no matter where you are selling it.

8. Changing Customer Demand

One of the emerging inventory management trends is changing customer demands. Today, customer demands are constantly changing, which means that businesses can witness a sudden spike in sales or a significant drop in demand. This unpredictability can make it challenging to maintain optimal inventory levels.

Solution: To tackle changing customer demands, you have to be responsive and agile to changing demands. You have to use the right inventory and sales management tool, like C2W Inventory, that can provide you with real-time data and useful insights into sales, inventory levels, and more. This way, you can analyze such insights and make the right decisions about the inventory level.

9. Managing Perishable and Fragile Stock

Perishable stock (dairy products, fresh produce, and others) and fragile stock (electronics, glassware, and others) need special care during storage and transit. Due to their limited shelf lives, they require strategic planning to sell before they expire or are damaged.

Solution: The best way to manage perishable and fragile stock is to use an inventory management system that can also record their expiration date, temperature control, and other details. This way, you can better know about your perishable and fragile stock.

10. Scaling Inventory Management System

With business growth, inventory management needs also grow. There will be more items and sales to manage. This makes it challenging to manage inventory if the current system is not scalable.

Solution: Scaling an inventory management system is a breeze if you use a scalable system from the first day. For example, C2W Inventory offers a full-fledged inventory management system that can scale as your business grows. Its centralized multi-warehouse management, real-time inventory visibility, automated order fulfillment, and much more make it easy to scale inventory management to any level.

C2W Inventory: Your Ultimate Solution for Inventory Management Challenges

From the above discussion, it is evident that most inventory management challenges are solvable if you use reliable inventory management software. That’s what C2W Inventory promises to offer.

C2W Inventory is a powerful inventory management software that helps to streamline all inventory-based activities. Its feature-rich functionalities make it a one-stop solution for almost all inventory management challenges.

Some of the key features of the C2W Inventory are as follows:

Multi-Warehouse Management:

It offers an all-in-one, centralized dashboard to view, organize, and move stocks within multiple warehouses.

Real-Time Inventory Visibility:

It provides real-time visibility of inventory levels, allowing users to track stocks easily and avoid situations of overstock/stockouts.

Order Fulfillment Workflow:

It automates order fulfillment processes, streamlines customer management, and provides sales analytics for strategic decisions.

Stock Alerts:

It can send timely alerts on specified low stock levels.

Mobile SmartScan:

Its Mobile SmartScan system streamlines order processing by supporting real-time barcode scanning for picking orders, transferring stock, receiving goods, and more.

Reports and Analytics:

It offers insightful reports that provide details about products, sales, and trends.

Integration:

It can integrate with Shopify, Amazon Services, APC, Shippo, and other third-party tools.

Overall, C2W Inventory provides a comprehensive toolkit to eradicate inventory management challenges and streamline all the activities related to the purchase, sale, and management of inventory.

So, why struggle with inventory management challenges when you can handle your inventory proficiently with C2W Inventory? Therefore, get your hands on C2W Inventory software and optimize your inventory management.